Kerr Pump & Supply is a preferred distributor of Alfa Laval heat exchangers. Alfa Laval is a leading global provider of first-rate products in the areas of heat transfer, separation and fluid handling. For more than 125 years, Alfa Laval has been producing specialized products and solutions to heat, cool, separate and transport products, such as oil, water, chemicals, beverages, foodstuffs, starch and pharmaceuticals.

Kerr Pump specializes in heat exchangers and will work with you to find the right solution for your needs. We are the area’s expert in heat exchange technology and are proud to offer Alfa Laval as a premier brand.

Kerr is an Alfa Laval distributor in Michigan for their full line of heat exchanger solutions.

Alfa Laval T Series Heat Exchangers

Alfa Laval’s next generation T-Series gasketed plate heat exchangers maximize production and minimize energy consumption. These next generation plate-and-frame-heat exchangers offer improved thermal efficiency, increased reliability and simplified service.

The latest advances in gasketed plate heat exchangers for industrial applications boost thermal transfer with a new FlexFlow™ plate design that improves thermal efficiency and optimizes thermal drop utilization, and CurveFlow™ distribution area that optimizes the flow of media to better use the whole plate surface.

The Alfa Laval T series heat exchangers offer other innovative design features like an offset gasket groove in a zig zag pattern to increase heat transfer area. Beyond that, they are designed with a non-circular inlet and outlet for enhanced throughput and lower pressure drop.

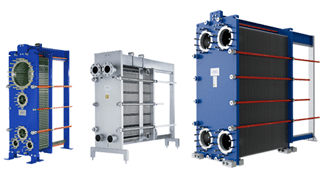

Alfa Laval Heat Exchanger Types

Kerr offers a range of proven Alfa Laval heat exchanger types suitable for your application.

- Brazed plate heat exchangers

- Fusion-bonded plate heat exchangers

- Gasketed plate-and-frame heat exchangers

- Plate and shell heat exchangers

- Welded plate-and-frame heat exchangers

Alfa Laval Brazed Plate Heat Exchangers

Constructed without gaskets, brazed plate heat exchangers can be optimized for a great range of pressures and temperatures. These corrosion resistant heat exchangers are suitable for many applications in cooling, heating, evaporation and condensing. In addition, brazed plate heat exchangers:

- provide efficient heat transfer with a small footprint

- are maintenance free

- offer long service lifetime

- withstand high temperatures and extremely high design pressures

Alfa Laval Fusion-bonded Plate Heat Exchangers

Alfa Laval fusion-bonded heat exchangers are 100% stainless steel units consisting of corrugated stainless steel plates, a frame plate and a pressure plate. The heat transfer plates in the plate pack are bonded together using unique active diffusion bonding technology.

Fusion-bonded plate heat exchangers:

- provide efficient heat transfer with a small footprint

- are maintenance free

- provide a long service lifetime

- ensure low life cycle costs even under high-temperature conditions

- handle very high temperatures or extremely high pressures

These heat exchangers are a gasket-free alternative for industrial applications that use aggressive liquids or require cleanliness.

Gasketed Plate-and-Frame Heat Exchangers

Gasketed plate and frame heat exchangers offer accurate fluid temperature control for heat recovery, and are often used for food or sanitary applications. The heat transfer area of a gasketed plate heat exchanger is made up of corrugated plates assembled between a frame and pressure plates to retain pressure. Gaskets between the plates act as seals, and fluids normally run counter-currently through the heat exchanger.

Gasketed plate heat exchangers:

- Offer high thermal efficiency and close temperature approach

- Include Compact units – space saving, easy to service and maintain

- Provide maximum uptime with less fouling, stress, wear and corrosion

- Are easy to adapt to changed duty requirements

Alfa Laval Plate and Shell Heat Exchangers

Welded plate and shell heat exchangers provide a robust solution for challenging high pressure process duties. Designed for high temperatures and high pressures, these heat exchangers deliver efficient heat transfer with a small footprint.

Benefits of plate and shell head exchangers include:

- More uptime and longer life due to greater fatigue resistance

- Higher operating pressures thanks to robust, patented construction

- Exceptional thermal performance

- Installation savings through compact, lightweight design

- Reliability as a result of closed, fully welded construction

Semi-Welded Plate-and-Frame Heat Exchangers

Alfa Laval semi welded plate-and-frame heat exchangers have a mix of welded and gasketed plates. The two plates are welded together and gasketed to other pairs within the heat exchanger. The sealing system guarantees a long lifetime sealing between the welded channels because the laser weld is on the outside of the ring gasket groove.

Semi-welded plate heat exchangers are designed for refrigeration, chemical processes and industrial utility duties. In addition they are:

- Highly efficient and flexible

- Space-saving compact units

- Cost effective owing to superior energy efficiency and long service intervals

- Safe and reliable sealing with no risk of cross-contamination

- Resistant to pressure and temperature fatigue

Heat Exchanger Inventory at Kerr Pump

We inventory several key items within the Alfa Laval line and can design heat exchangers into your pump skid or pump system to achieve your end goal.

- Alfa Laval Plates

- Alfa Laval Heat Exchangers on Pump Skid – expandable if system needs grow

- Alfa Laval Heat Exchangers on Pump Skid

Alfa Laval Feature Articles

Alfa Laval Heat Exchangers for Machinery & Manufacturing Applications – Focus on Fluid Power, Metal Working, Hydraulic Oil

Vendor Feature: Heat Exchangers: Alfa Laval – Downloads for Top Ten Maintenance Tips, Heating & Cooling Fluids Handbook, Cooling the Internet Case Study

Watch Alfa Laval Videos

(To see video choices, open playlist using the upper menu bars) ![]()