Kerr Pump & Supply is a ThermaPlate distributor offering the ThermaPlate heat exchanger line to customers in Michigan. ThermaPlate boasts decades of experience designing and manufacturing pillow plate type heat exchangers. ThermaPlate’s ASME certified shop uses the latest technology in resistance and laser welded pillow plate manufacturing.

ThermaPlate distributor Kerr Pump & Supply stocks ThermaPlate heat exchanger solutions including immersion plates, plate banks, integral tank jackets, clamp on plates and custom assemblies.

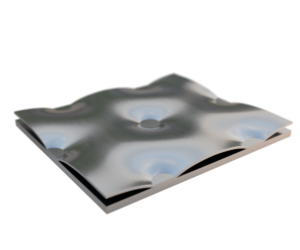

Pillow Plate Technology

Each ThermaPlate heat exchanger features pillow plate technology. Pillow plates surfaces consist of two flat sheets of material that are fuse welded together with a strategically positioned welding pattern. The result is a fully welded and inflated ThermaPlate heat exchanger surface.

Each ThermaPlate heat exchanger features pillow plate technology. Pillow plates surfaces consist of two flat sheets of material that are fuse welded together with a strategically positioned welding pattern. The result is a fully welded and inflated ThermaPlate heat exchanger surface.

Pillow plates are available with various interior circle weld patterns designed for specific service types performance requirements.

Immersion Plates

Simple and cost-effective immersion plates are ideal to add heating or cooling to an existing tank, or to ensure that the heat exchanger remains independent for convenient service or replacement. ThermaPlate immersion plates are available in several designs suited for applications that use liquid, steam, or refrigerants as the heating or cooling source.

Immersion plate options include:

- Material thicknesses

- Material Type

- Baffle configurations

- Range of sizes

- Handles

- Hangers

- Bang Pads

- Nozzle Sleeves

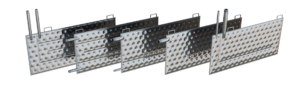

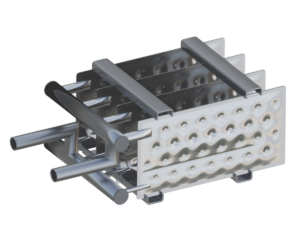

Plate Banks

Plate banks are ideal for heating or cooling applications where the thermal load is more than a single plate can handle. All of the plates are connected using a single inlet and outlet connect for easy installation.

Plate banks are available in several styles:

- Immersion banks for submersion into a flooded liquid tank or body of water

- Insertion plate banks mounted to the outer surface of the process equipment

- Bayonet style plate bank assemblies that are flange mounted to API vessels and storage tanks

- Ducted plate banks for heat recovery applications from ventilation lines

Plate bank options include:

- Total plate count

- Plate size

- Plate thicknesses

- Materials of construction

- Header locations and connection types

- Plate brace or mounting brackets

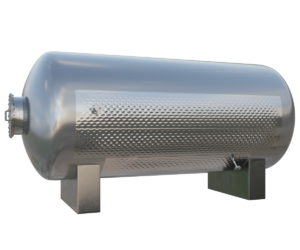

Integral Tank Jackets

Integral tank jackets for new vessel construction are an easy, cost-effective way to reduce your tank fabrication time. ThermaPlate integral tank jackets are used for:

- Vertical tank jackets

- Horizontal tank jackets

- Flat sided tank jackets

- Jacketed components

Flat tank shell materials are delivered with THERMAPLATE surface preinstalled. Once the main shell is assembled, jacket connections can be installed, and the ThermaPlate jacket can be inflated to the designated pressure and pillow height.

Integral tank jackets are available:

- single embossed or double embossed

- in various plate thickness material combinations for storage tanks, processors, and reactors

- in configurations optimized for steam, thermal fluids, and refrigerants

- with ASME, PED, or CRN certifications

Clamp on Plates

THERMAPLATE clamp on plates are a simple, cost-effective, fully customizable solution to add external heating or cooling to an existing tank or surface. They can be installed quickly with little to no site welding or equipment alterations with specially designed mounting hardware. Configurations available include:

- Curved clamp-on jackets

- Flat surface clamp-on jackets

- Curved clamp on jackets for horizontal vessels

Clamp-on plates:

- single or double embossed THERMAPLATE heat transfer surface construction

- Each clamp-on section shaped to fit

- Equipped with mounting lugs to keep continuous tension or force on the plates

- can be provided with ASME, PED, or CRN certification.

- be designed for any service – steam, thermal fluids, refrigerants

To enhance the performance of a clamp-on jacket, a heat transfer compound is recommended.

Applications for ThermaPlate Heat Exchangers

ThermaPlate heat exchangers are available in various styles for a range of applications including:

- General heating or cooling

- Geothermal

- Thermal storage and ice banks

- Fluidized bed dryers

- Thermal melting

- Gas re-heaters

- Contaminated air heaters

- Fluidize bed dryers

- Solids cooling and heating systems

- Suction heaters for viscous product storage tanks

- Tank sump heating and cooling

- Heat recovery from ventilation

- Bulk solids heating, cooling, and drying

- Particulate air cooling and drying

- Heat or cooled process mix tanks

- Refrigerated silos

- Fermentation and reaction tanks

- Reactor vessels

- Storage tanks

- Heat or cooled tanks

- Refrigerated tanks

- Storage tanks

- Jacketed totes

- Solids hoppers and shuts

- Flat sided tanks

- Open top rectangular vessels

- Rolled barrels or tank shells

- Dished or conical heads

- Flat heads and end plates

- U troughs

Let the Kerr Sales Engineers help you select the right solution for you.