Kerr Pump & Supply is an official stocking distributor of MD-Kinney products, a division of Ingersoll-Rand (formerly Tuthill). MD-Kinney is the manufacturer of Kinney® vacuum pumps and MD Pneumatics™ blowers & vacuum boosters.

MD-Kinney manufactures high performance, reliable positive displacement blowers, mechanical vacuum pumps, vacuum boosters and engineered systems ready for startup. They are designed for automotive, aviation, chemical, construction, energy & power, food & beverage, packaging, pharmaceutical, plastics, water & wastewater.

If you have a Tuthill blower, we can still help you with parts, repairs and replacement pumps. Contact us directly.

Kerr Pump & Supply can quickly ship your MD Pneumatics® blowers and vacuum boosters order. We offer the following products:

MD Pneumatics Blowers

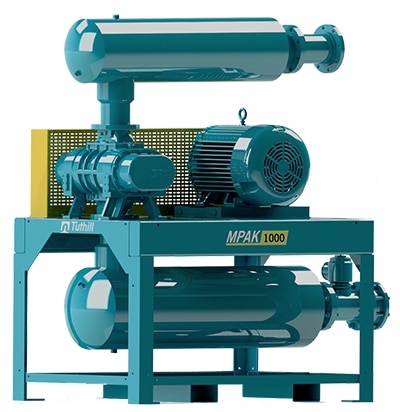

Blower Packages

Kerr offers MD Pneumatics open and enclosed blower packages for applications like pneumatic conveying and wastewater treatment. MD Pneumatics can also design and manufacture custom blower packages specific to your needs.

MPAK is value-engineered to meet specific applications and designed for simple installation. Open and enclosed blower package configurations provide flow from 250 to 1985 CFM, pressure from 5 to 15 PSI, and vacuum from 12” to 17” Hg. MPAK packages are sized with air blowers and backed by premium customer service.

Blower packages are engineered with options, cost effective, maintenance friendly, easy to operate, ready to go, easy to move, and retrofittable. Many additional features allow total customization of your blower package.

Rotary Positive Displacement CP Series Blowers

Air blower, rated up to 18 PSI / 16 “Hg vac. and designed to be interchangeable with equivalent sizes of competitive models.

- Triple lip seals standard on all models

- Sight glasses standard on all models

- Magnetic drain plugs standard on all models

- Timed with precision helical gears, keyed to the rotor shafts

- Include double-row ball bearings at the gear end

- Rotors with integral shafts

- Reduced noise versions available with tri-lobe rotors

- Bi-directional rotation

- Dual oil splash lubrication at both gear and drive ends available on some models

Rotary Positive Displacement Equalizer Blower

Air blower, rated up to 18 PSI / 17 ” Hg vac., high flow, and compact. Interchangeable with equivalent sizes of competitive models.

- Compact design

- Available in popular 4.5” and 6” gear diameters

- Bi-directional rotation

- Timed with precision helical gears, keyed to the rotor shafts reduces noise

- One piece housing

- Rotors with integral shafts

- Flow configuration is field convertible from horizontal to vertical

- Positive, locked-in end clearances to prevent internal contact and polished sealing surfaces

Rotary Positive Displacement – PD Plus Blower

Air and gas blower, rated up to 18 PSI / 17 “Hg vac. These are premium blowers renowned for their quality, dependability and outstanding performance.

- PD Plus Blowers 1200 Series – Up to 15 PSIG (1.03 bar g) pressure boost or 15” Hg (-500 mbar g) dry vacuum (24” Hg [-810 mbar g] water injected).

- PD Plus Blowers 3200 – Up to 15 PSI pressure or 17” Hg dry vacuum (24” Hg water injected).

- PD Plus Blowers 4000 – Up to 18 PSIG (1.24 bar g) pressure boost or 17” Hg (-575 mbar g) dry vacuum (24” Hg [-810 mbar g] water injected).

- PD Plus Blowers 5500 – Up to 18 PSIG (1.24 bar g) pressure boost or 17” Hg (-575 mbar g) dry vacuum (24” Hg [-810 mbar g] water injected).

- PD Plus Blowers 7000 – Up to 18 PSIG (1.24 bar g) pressure boost or 17” Hg (-575 mbar g) dry vacuum (24” Hg [-810 mbar g] water injected).

- PD Plus Blowers 9000 – Up to 15 PSIG (1.03 bar g) pressure boost or 15” Hg (-500 mbar g) dry vacuum (24” Hg [-810 mbar g] water injected).

Rotary Positive Displacement Qx Blower

Air blower, rated up to 18 PSI / 17 “Hg vac. High performance, energy efficient, low-noise line designed for long operating life at maximum operating conditions.

- High efficiency at high pressure and vacuum

- Bi-directional rotation

- Timed with precision helical gears, keyed to the rotor shafts

- Includes double ball bearings on timing gear end for additional strength and single roller bearings on drive shaft end of the machine

- L10 bearing life of up to 200,000 hours

- Tri-lobe rotors offer reduced pulsation and lower noise levels

- Oil lubrication on both ends with easy to view sight glasses allowing quick maintenance

- Features larger shaft diameters compared to competing manufacturers

MD-Kinney Vacuum Boosters

Vacuum boosters used with all types of vacuum pumps. Utilized in the manufacture of chemicals, petrochemicals, plastics, food processing, and many other applications.

Vacuum boosters are used to “supercharge” vacuum pumps to greatly extend pump performance. This allows for much faster pumping speeds and deeper vacuum levels. MD-Kinney vacuum boosters are utilized worldwide in the manufacture of chemicals, petrochemicals, plastics, semiconductors and wood composites as well as food processing, vacuum furnace applications and many other general applications in industry. They are available up to 10,000 CFM with a variety of different seals and lubrication options.

Mechanical Seals, Integral Pressure Lubrication

These series incorporate mechanical seals on the rotor shafts and the drive shaft, flanged port fittings, water cooled drive shaft seal, integral pressure lubrication system with water cooled heat exchanger, and cooling coils in the end covers. Water cooled drive shaft seal not included with optional motor mounting flange versions.

Slinger Seals, Integral Pressure Lubrication

These series utilize a mechanical drive shaft seal in conjunction with a non-contacting, non-wearing slinger seal on the rotor shafts, flanged port fittings, water cooled drive shaft seal, and integral pressure lubrication system with water cooled heat exchanger. Cooling coils are not included.

Mechanical Seals

These series incorporate mechanical sealing on the rotor shafts and the drive shaft, flanged port fittings, water cooled drive shaft seal, and cooling coils in the end covers.

Slinger Seals

These series utilize a mechanical drive shaft seal in conjunction with a non-contacting, non-wearing slinger seal on the rotor shafts, water cooled drive shaft seal, flanged port fittings, and are dependable performers for air and many gas applications. Cooling coils are not included.

Kerr also offers MD-Kinney Vacuum Pumps & Systems.

Learn more about Kerr’s entire selection of Blowers.