Pump Package Systems & Components

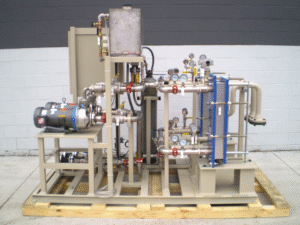

Kerr Pump and Supply helps industry solve process problems with computer designed, skid mounted, engineered pump package systems.

https://www.youtube.com/watch?v=Vb5Vs3tyJCUWhat is a Packaged Pump System?

A packaged pump system is a pre-assembled and pre-engineered pumping solution designed to move fluids from one location to another. Kerr manufactures complete, self-contained pumping units that are ready to move fluids, ranging from simple pump package systems to smart solutions with PLC automation and touch-screen HMI controls.

The key features that characterize a packaged pump system include:

- Pre-assembly and testing before delivery.

- Compact design for space-saving installation.

- Plug-and-play setup with minimal on-site work.

- Integrated controls for automation and efficiency.

- Customized design to meet specific application needs.

Benefits of a Packaged Pump System

Each packaged pump system offers several advantages over traditional pump installations.

1. Easy Installation

Each Kerr packaged system is skid mounted, pre-wired, pre-piped, and factory tested to simplify on-site installation and reduce setup time. Each unit is hydro-statically tested at the factory to ensure trouble-free start-up. Minimal piping and wiring requirements make deployment quicker and easier, and plug-and-play operation allows for immediate use upon delivery.

2. Compact Design

Each custom designed pump package is engineered and mounted on a skid with the specific objective of saving space, eliminating the need for separate pump houses or large mechanical rooms.

3. Cost Savings

Systems are designed to minimize cost. Pre-assembly lowers installation and labor costs, while energy-efficient designs lower operational costs.

4. Optimized Performance

Systems are factory-tested to ensure all components work together seamlessly, offering consistent performance with optimal pump and motor matching.

5. Customization

Kerr ‘s custom designed pump packages are tailored to the application’s exact requirements, including the application, flow rate, pressure requirements, and site conditions. Optional add-ons like Variable Frequency Drives (VFDs) for energy efficiency.

6. Improved Energy Efficiency

Advanced control systems optimize pump performance and reduce energy consumption. VFDs adjust motor speed based on demand, preventing unnecessary energy use, and smart monitoring systems help detect inefficiencies and prevent wasted energy.

7. Simplified Maintenance

Kerr custom engineered package systems are designed for ease of maintenance and serviceability, with easy to access components and readily available spare parts.

8. Compliance with Industry Standards

Systems are designed to ensure compliance with local building codes and industry regulations.

9. Scalability

Modular designs allow for system upgrades as demand increases, or systems can be easily integrated into existing infrastructure without major modifications.

Packaged Pump System Applications

Packaged pump systems are used in a wide range of applications across different industries due to their efficiency, ease of installation, and reliability. These systems are suitable for various fluid handling needs, including water, oil, and other liquids.

Water Supply & Pressure Boosting – Booster pump packages used in commercial buildings, industrial facilities, and municipal water systems.

Wastewater & Sewage Handling – Submersible and grinder pump packages used for sewage lift stations, wastewater treatment, and stormwater flood control.

HVAC & Cooling Systems – Centrifugal pumps for chilled water and condenser water circulation, district cooling, and boiler feedwater.

Fire Protection – Fire pump systems providing water supply for sprinkler and hydrant booster systems and NFPA-compliant fire suppression systems.

Irrigation & Agriculture – High-efficiency pumps for large water volumes to ensure efficient water distribution for crops through farmland irrigation and greenhouse watering systems

Industrial & Manufacturing Processes – Pumps for a variety of chemical and pharmaceutical processing, cooling and heat exchange systems, and process water supply and food, and beverage production processes

Mining & Construction – Rugged pumps for dewatering in mines and tunnels, dust suppression at construction sites, and slurry and sediment pumping

Difference Between Process Skid Systems and Pump Package Systems

Kerr offers both process skid systems and pump package systems. Both are modular solutions designed for efficiency, although they serve distinct purposes:

Process Skid Systems integrate multiple process components, including pumps, valves, instrumentation, controls, and other industrial equipment into a single unit. They are custom designed for complex processes such as chemical dosing, heat exchange, mixing, or filtration, providing a complete process solution.

Pump Package Systems focus specifically on fluid movement and pressure control for a specific system. They include a pump, motor, and necessary piping within a skid-mounted frame. Pump packages are typically used for applications that require precise fluid transfer but do not need additional process components.

Types of Packaged Pump Systems

Kerr offers several types of packaged pump systems come, each designed for specific applications.

Booster Pump Systems

Booster pump systems are used to increase water pressure in buildings, industrial plants, commercial facilities and municipal water systems. They often feature Variable Frequency Drives (VFDs) for energy efficiency, and may have multiple pumps for redundancy and load sharing.

HVAC & Chilled Water Pump Systems

Skid mounted pump systems are used in heating, ventilation, and air conditioning (HVAC) systems for circulating water. They often feature built-in controls for load balancing and variable speed operation for energy savings.

For example, Kerr’s Custom Temperature Control Units (TCUs) are tailored to your specific requirements to pre-heat or pre-cool your circulating process fluid and then automatically maintain your needed temperature range with heating or cooling as required.

Other examples include:

- Cooling tower pump systems that extract heat from water by evaporation

- Chilled water pump systems used to cool the building’s air and equipment

- Closed Loop Hot Water Generation pumps that use the ground around or under a building as their heat source, circulating water to collect the energy in the ground and deliver it to a water source heat pump

- Compressor Cooling systems that reuse returning vapor or water to cool motor windings

- Induction Cooling Systems that use pumps to circulate water through a furnace to absorb heat and then to a cooling tower where the heat gets released

Industrial Process Pump Systems

Industrial process pump systems are used in manufacturing and process industries to transport liquids, chemicals, or slurry used in chemical processing, food and beverage, pharmaceutical production, mining, and other applications. These pump systems may include corrosion-resistant materials for handling aggressive fluids, with positive displacement or centrifugal pump options, as well as optional custom automation and monitoring.

Other Types of Packaged Pump Systems

Wastewater & Sewage Lift Stations

Lift stations are designed to move wastewater from lower to higher elevations when gravity flow is not possible for municipal sewage systems, industrial wastewater treatment, stormwater drainage. These systems feature submersible or dry-pit pumps, grinder pumps for solids handling, and control panels for automatic operation.

Fire Pump Systems

Specifically built for industrial fire protection, fire pump systems include jockey pumps to maintain system pressure.

Irrigation Pump Systems

Irrigation pump systems are designed to deliver water efficiently for agricultural, landscape, and golf course irrigation with high-volume water delivery.

Dewatering Pump Systems

Dewatering pump systems are used to remove water from construction sites, tunnels, mines, and flood-prone areas. These packaged systems include high-capacity pumps for rapid water removal, in submersible and dry-mount configurations.

Blower Systems

Blower Systems for Pressure and Vacuum Service are used for collection of dusty air to a central collection point in manufacturing plants. It also can be used to hold pieces of material in place on a table in the garment industry. Learn more about Blowers here.

Heat Exchanger Cleaning Systems

Heat Exchanger Cleaning is done by acid cleaning, sandblasting, and high-pressure water. For large scale heat exchangers, water purification and addition of chemicals are used. Learn more about Heat Exchanger systems here.

Packaged Pump System Components

Kerr manufactures fully integrated packaged pump systems that are completely customized with all the components essential to your pump application – pumps, motors, piping, valves, controls, electrical accessories, and other necessary components, all mounted on a common base frame. Each component is selected for overall system compatibility, durability and cost effectiveness.

Pumps

The fluid-moving core of the system starts with the highest quality commercially available pumps from major manufacturers to reduce maintenance and eliminate costly downtime. The type of pump – centrifugal, submersible, diaphragm, or positive displacement, etc. – varies based on the application.

Motors

Energy efficient motors provide the power to drive the pumps.

Control Panel

Custom controls & automation options manage the operation of the pump system, ensuring efficiency and allowing for automation and monitoring. Variable Frequency Drives (VFDs) can be used to adjust pump speed based on demand for energy efficiency and remote monitoring capabilities. We can provide UL508A and UL698A approval for any control panel that is provided on a package. Learn more about Kerr Control Panels division.

Piping & Valves

Piping and valves direct and control fluid flow, ensuring smooth operation and preventing backflow.

Pressure Tanks (if applicable)

Pressure tanks may be used in booster and fire pump systems to maintain pressure stability.

Sensors & Instrumentation

Pressure sensors, flow meters, temperature sensors, level sensors and more ensure proper monitoring and automation.

Skids

Kerr’s skid mounted pump systems feature a sturdy platform that houses all components – pumps, motors, gauges, valves, piping and controls – securely assembled on heavy duty groutable skids for ease of handling, transportation and installation.

Custom Designed Pump Packages for Your Requirements

Kerr custom designs each packaged pump system based on the unique application and site requirements including:

- space constraints

- power supply availability

- environmental factors such as temperature extremes, corrosive conditions, and explosion-proof requirements

- required flow rate (GPM)

- required pressure (PSI or bar) at the delivery point

- total dynamic head (TDH) considering elevation changes, friction losses, and required outlet pressure

- required compliance & certifications for municipal or industrial standards

Kerr Packaged Pump Systems

Kerr manufactures pump systems for all industries, all components, completely integrated with Kerr control panels. All systems are custom designed in house to agreed specifications.

Kerr Experience

Kerr has been supplying manufacturing plants with a full line of pumps, heat exchangers, blowers, vacuum equipment and related process equipment since 1905. Our years of field proven experience enable us to accurately evaluate operating conditions, anticipate problems and provide for future system requirements.

Kerr Service

If any of our custom engineered pump package systems should require service, our factory certified technicians get your system back on line quickly. Kerr assumes total system responsibility on every Kerr packaged system.

Contact Kerr Pump & Supply to customize a pump package system for your requirements.

- Get expert advice on selecting the right package for your needs.

- Request detailed pump performance curves and technical specifications.

- Ask about customization options for your specifications.