Kerr Pump & Supply offers field service for pumps and pump systems at your facilities for the utmost in convenience and response time.

Kerr Pump Field Service offers:

- Around The Clock support for maximum equipment “uptime”

- Factory Trained and Certified Service Technicians

- Diagnostics and maintenance performed to manufacturer’s specifications

- Insured Service Technicians

- Liability Protection

- Service for All Makes of Equipment

- Single Source Supplier for Service and Parts

- Customized Preventative Maintenance Contracts available

- Tailored to meet the specific needs of each customer

Here are some examples of our pump field service offerings.

Pump Inspections and Preventive Maintenance

Kerr highly recommends Inspections and Preventive Maintenance annually or quarterly depending on equipment usage. Any pump that is in operation can benefit from annual inspections and preventive maintenance. These are especially useful in the high volume food industry for vacuum pumps and control valve replacements.

Cooling Tower and Fire Supression Split-Case Pumps

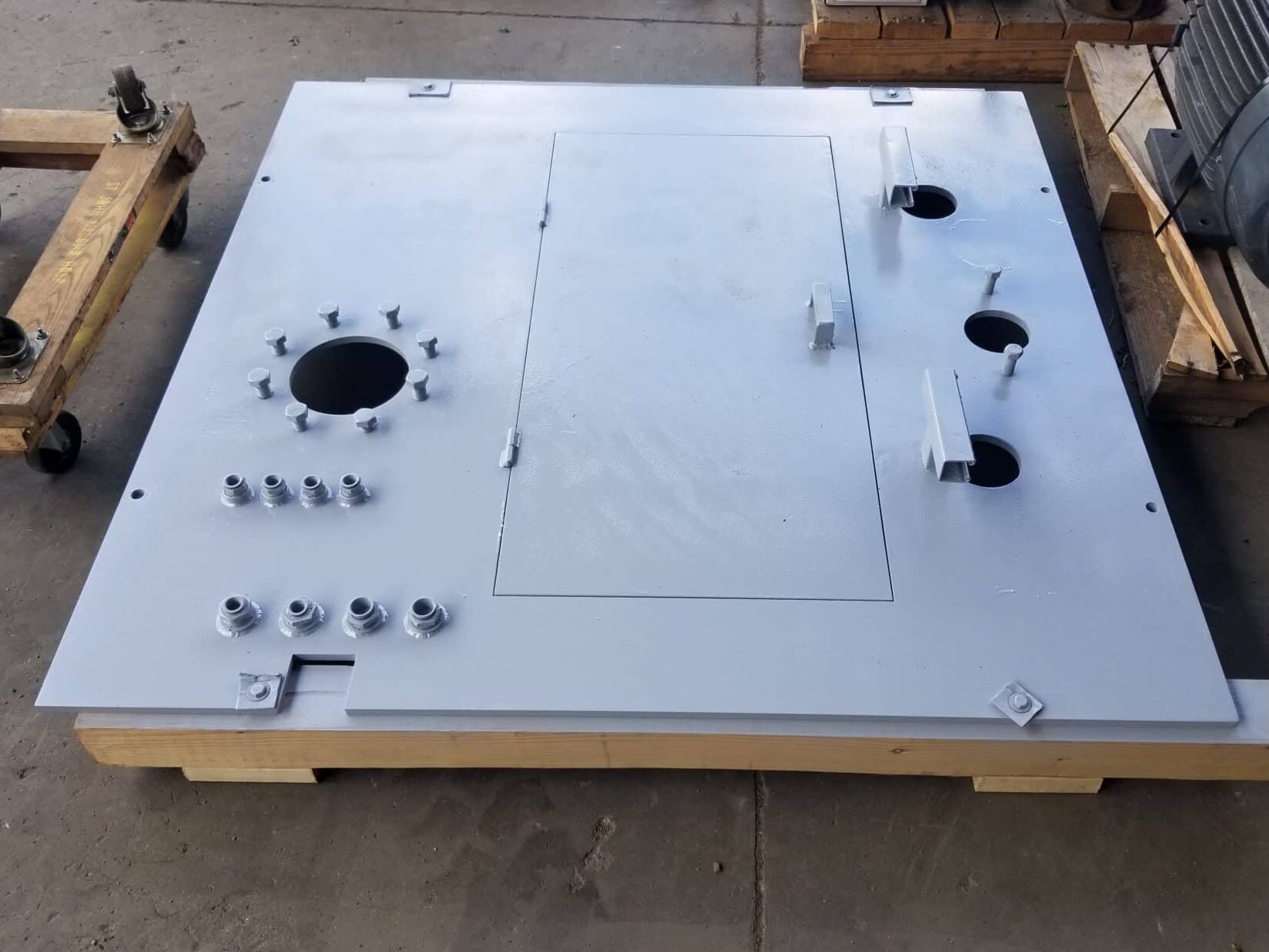

Complete Lift Station Overhaul

Kerr offers complete lift station overhauls that include a complete inspection and service on pumps, rails, piping, valves, custom wet well covers, floats and controls.

Booster Pump Packages Service

Kerr offers booster pump package service including Variable Frequency Drive adjustments.

Vacuum Pump Installation / Service / Preventive Maintenance

Kerr has extensive knowledge in the vacuum pump installation, service and preventive maintenance area.

Centrifugal / End Suction / Municipal Sewage Applications

Kerr offers extensive field service for centrifugal, end-suction and municipal sewage applications. Yes, even the dirty jobs.

Valve Replacements

Kerr does extensive work with valve replacements that are often installed with pumps. This includes Check valves, Isolation valves, Pressure reducing valves, Plug valves, Balancing valves, and Modulating valves.

Laser Pump Alignment with Report

A properly aligned pump is more efficient, has a longer life and helps you avoid unnecessary pump repairs and downtime. If your pump is noisy, it could be misaligned. Kerr has the tools necessary to align your pump in the field and provide you with a complete report. Learn more about Laser Alignments.

Fire Pump Flow Testing with Report

Kerr is specially equipped for Annual Fire Pump Flow Testing on-site with a full report for fire marshall certifications.

Confined Space Entry for Pump Repairs

Kerr is certified for repairs in confined spaces – defined as 4 ft or more with only one exit. We use air monitors, oxygen pumps and safety harnesses to assure worker safety. We have 2 crane trucks for lifting equipment. We do a significant amount of work for MDOT – rest areas, lift stations.

Pump Field Service Customer Stories

-

Control Panel Upgrade in Winter

This exterior control panel upgrade was accomplished during the middle of winter.

-

Pump Station Inspection & Repair

During a Pump Station Inspection, we thoroughly evaluate all components, photographing and documenting so you will know exactly what repairs or replacements are needed.

-

Case Study – Lincoln Park – Lift Station Controls

Kerr recently helped the City of Lincoln Park to cut maintenance time and costs by relocating their lift station control panel with a turn-key solution in just one day.