Kerr recently helped the City of Lincoln Park to cut maintenance time and costs by relocating their lift station control panel with a turn-key solution in just one day.

Problem: Lift Station Controls Below Ground

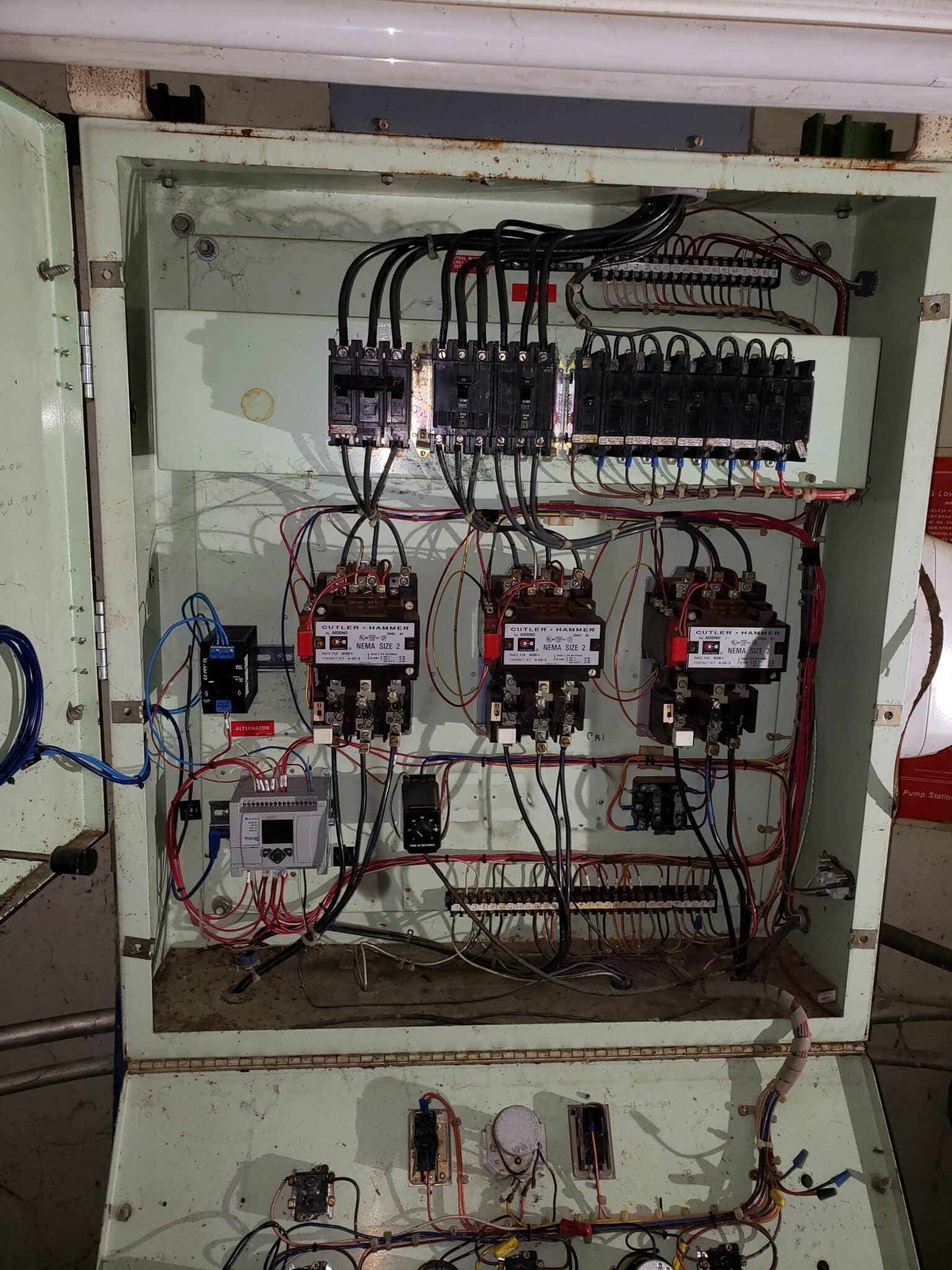

Recently Kerr was asked to move the controls of a lift station for the city of Lincoln Park from their Dry Pit (30 feet below ground) to be above ground. With the controls above ground, the operators would no longer have to go below to check wet well levels, check pump status or manually run a pump. Not only is this safer and easier for the operator, but it saves the city money (in manpower hours). This eliminated the need to unlock the station, harness up and go down into the pit, while another operator stayed above ground, in case the operator in the pit ran into trouble.

Old System Photos (click to enlarge)

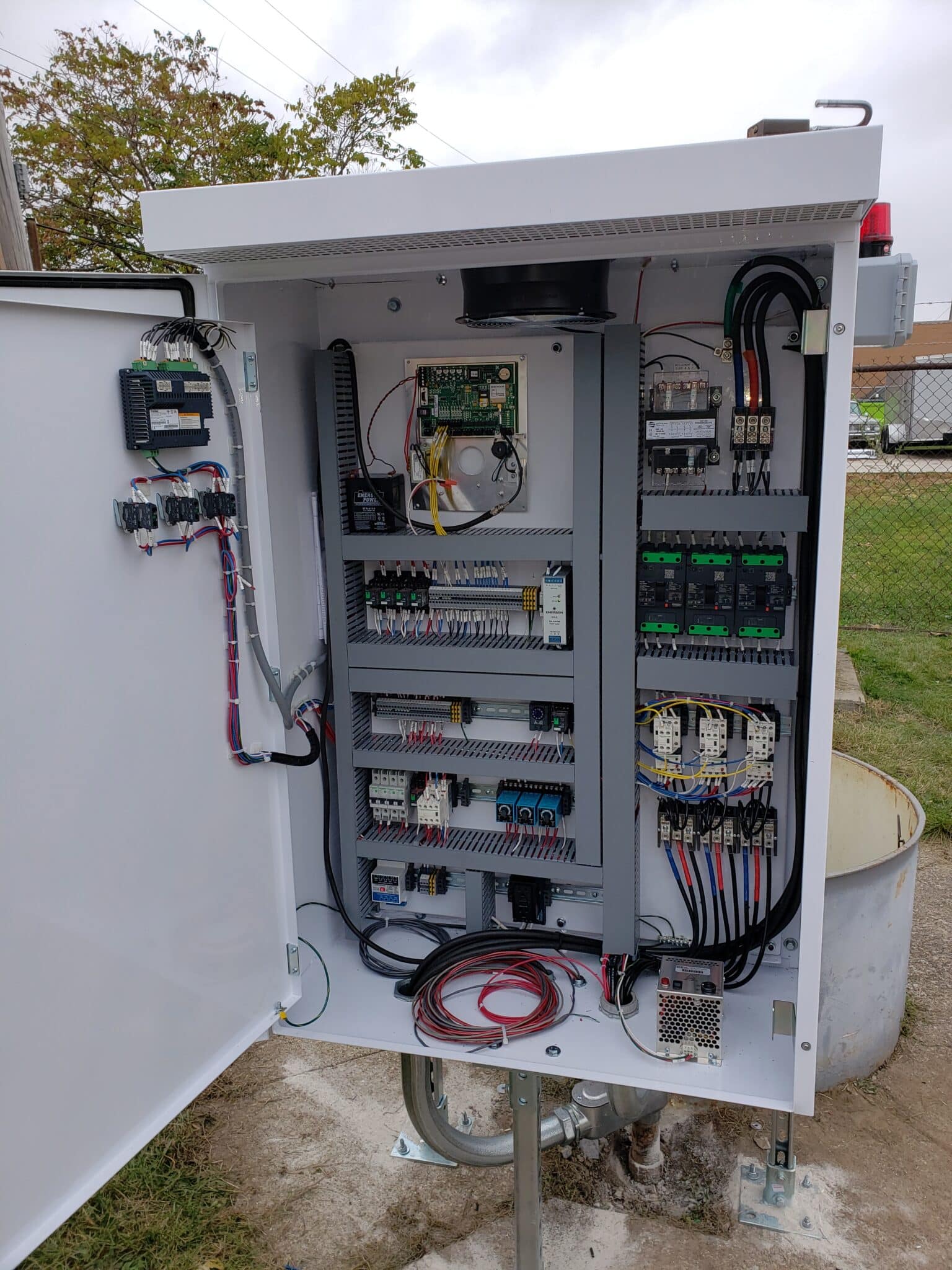

Solution: Installed new Control Panel in just a day

Kerr designed and built the cities new Triplex Control Panel for the (3) 10HP Dry Pit pumps. We used a Kerr Triplex Pump Controller to perform the pump sequencing, display status and log alarms. We were able to integrate their existing Mission system into the new control panel to maintain their remote monitoring capability as well as the existing level sensor and floats.

Result: Easier access to Control Panel & Reduced Maintenance Hours

New System Photos (click to enlarge)

Read our other posts on Lift Stations and Controllers

Packaged Lift Stations provide Operational and Cost Savings.