As a Dynamix Agitators distributor for the state of Michigan, Kerr Pump & Supply offers Dynamix’s complete line of industrial mixers and agitators that are used in chemical and industrial processes worldwide. Dynamix Mixers are configured for each specialized process, and designs are stress tested to perform in demanding environments to guarantee mixer performance.

Kerr Pump works with Dynamix Agitators to provide solutions for the Water & Wastewater, Mining, Chemical, Brewing & Distilling, Paint & Coatings, Adhesives & Sealants, Oil & Gas, and Agriculture industries. With 45 years industrial mixing experience, Dynamix Agitators produces mixers used by many of the most respected companies around the globe.

Kerr Pump & Supply, your Dynamix Agitators distributor in Michigan, can assist with your Dynamix Agitators order, parts, and service.

Large Volume Tank Mixer – NMX Series

Industrial tank mixers that handle volumes greater than 10,000 gallons require heavy duty engineering for some of the most demanding industries and applications.

Robust, configurable NMX industrial agitator mixers are used for heavy duty industry applications from 2,500 to 300,000 gallons. These mixers are both highly efficient and highly custom configurable. NMX series mixers feature:

- Heavy duty output bearings to optimize the gearbox for mixing applications

- Case-hardened, high-quality gearing

- Mount designs to suit your tank, flange, or plate

- Double or Quadruple Lip Seals, Packing, Mechanical Seals to suit your application or brand requirement

- 316 SS, 304 SS carbon steel, coated carbon steel, Hastelloy or special alloy materials of construction

- Rubber, PVC, Teflon or PVC coating

- Solid and hollow shaft designs

- Full selection of axial flow and radial flow impellers

Mid Size Tank Mixers – GMX Series

GMX Series mixers and industrial agitators for 10,000 to 100,000 gallon tanks are designed to handle all of your large tank mixing needs in an economical configuration, without sacrificing durability or efficiency. These high efficiency designs are configured for medium-duty applications, featuring a parallel shaft with high quality helical gears. They are also available with a low profile, right angle gearbox.

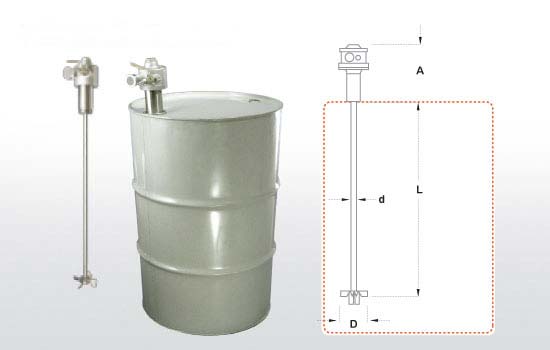

Drum Mixers

Drum mixers and barrel mixers are widely used in the process industries, and can be customized for your application needs. Dynamix 55 gallon drum mixers include for many applications and manufacturing processes.

Drum agitators can be mounted through a small 2″ NPT bung mount, with a lid to mount on an open top drum, or by clamping the mixer on the side lip of the drum. Barrel mixers are available in plastic and stainless steel models.

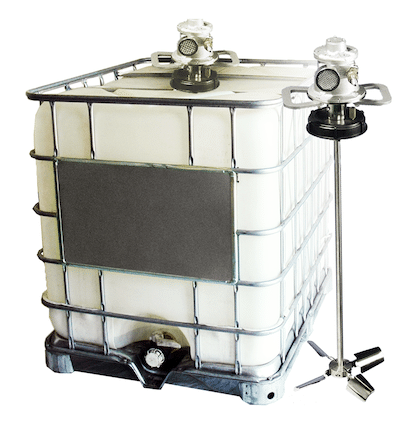

Tote Tank Mixers

Several models of Dynamix tote tank mixers and tote agitators are manufactured for mixing between 250 and 300 gallons.

One model, the Integrated Tote Mixer (ITM) converts your tote from a shipping vessel to a process tank. The Integrated Tote Mixer uses 4-bladed collapsible impellers to apply the torque principles of larger industrial agitators into a tote and guarantee its performance. It fully encloses the tote to ensure the product cannot be contaminated during the mixing process.

Side Entry Mixer – SMX Series

Dynamix side entry mixers are industrial mixers for 2,500 – 300,000 gallon mixing tanks. Side entry mixers are ideal for large storage tanks, large basins, or in other applications where top entry mixing is less economical or effective. These versatile mixers are equipped with standard NEMA C-face motors with a power range from 1 to 60 HP.

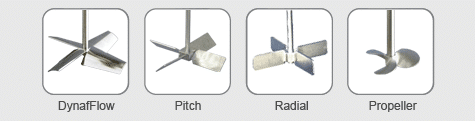

Portable Tank Mixer – DMX Series

Dynamix heavy-duty portable tank mixers for 300 – 3,000 gallon tanks can be either clamp or pedestal mounted. These widely used, portable industrial mixers can be configured to suit the most challenging applications. DMX Series mixers offer some of the highest service factors, with a market leading cycloidal gearbox capable of handling shock loads as high as 500% of the rated torque.

Portable mixers are available with Dynaflow impeller, pitch blade impeller, radial impeller, or propeller. The ideal impeller option depends on process requirements for uniformity, area of influence, shear, solid suspension, and other factors.

Read Dynamix Articles:

Watch Kerr Pump & Supply – Dynamix Agitators YouTube Channel

(To see video choices, open playlist using the upper menu bars)

Let the Kerr Sales Engineers design the right solution for your application