In the world of chemical processing, precision, durability, and safety are non-negotiable. Every component in your process—from storage tanks to agitators—must be engineered to handle aggressive materials, maintain chemical integrity, and perform reliably under demanding conditions.

At Kerr Pump & Supply, we understand the critical role industrial tanks and industrial mixers play in achieving efficient, consistent, and safe chemical processing. That’s why we partner with three of the industry’s most trusted names—ProQuip, Dynamix, and Amtrol—to deliver premium solutions tailored to your specific application.

Whether you are storing volatile chemicals, blending viscous materials, or maintaining precise mixing conditions for sensitive fluids, our product lines are designed to keep your operations running smoothly, day after day.

Why Industrial Tanks and Mixers Matter in Chemical Applications

Chemical processes often involve handling fluids that are corrosive, abrasive, temperature-sensitive, or highly viscous. This creates unique challenges:

-

Material Compatibility: Tanks and mixers must be constructed from materials that resist chemical attack, preventing contamination or equipment failure.

-

Precision Mixing: Many chemical reactions require consistent agitation to ensure uniformity and avoid separation.

-

Pressure & Temperature Control: Properly designed tanks and expansion systems help maintain safe conditions, avoiding dangerous pressure spikes or thermal stress.

-

Safety & Compliance: Equipment must meet strict regulatory standards to protect workers, products, and the environment.

By working with ProQuip, Dynamix, and Amtrol, Kerr Pump & Supply offers solutions that address these challenges head-on, delivering performance you can trust.

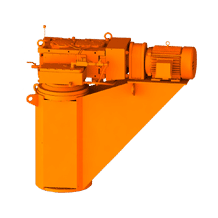

ProQuip: High-Performance Agitators & Mixers for Demanding Applications

Founded in 1969, ProQuip has built a reputation for manufacturing robust, application-specific mixing equipment.

Their top-entry, side-entry, and sanitary tank agitators are designed for maximum efficiency and longevity, making them ideal for industries like:

-

Chemical manufacturing

-

Pharmaceuticals

-

Paints & coatings

-

Food & beverage processing

-

Ethanol production

Key Features of ProQuip Mixers:

-

Mechanically Simple Designs: Fewer moving parts mean fewer breakdowns and lower maintenance costs.

-

Custom-Engineered Solutions: Each mixer is tailored to your process needs, from fluid viscosity to tank geometry.

-

Seal Options for Any Application: From single mechanical seals to double mechanical seals capable of handling pressures over 100 bar.

-

Full Horsepower Range: Gearboxes from fractional HP up to 1,000+ HP, with torque ratings exceeding 1,000,000 in-lbs.

-

In-House Testing: ProQuip can simulate your mixing conditions to ensure optimal performance before installation.

Whether you’re blending chemicals in a high-shear application or gently agitating sensitive materials, ProQuip delivers the reliability and performance your operation demands.

Video: Mixing High Viscosity Fluids with ProQuip Doubly-Pitched

Dynamix Agitators: Scalable Mixing Solutions for Industrial Tanks

With over 45 years of experience, Dynamix Agitators is a global leader in industrial mixing technology. Their products serve industries ranging from mining to pharmaceuticals, and they excel in designing mixers that scale to any tank size—from drums and totes to tanks exceeding 300,000 gallons.

Flagship Products:

NMX Series – Heavy-Duty Industrial Mixers

-

Designed for tanks between 2,500 and 300,000 gallons.

-

Built with high-torque gearboxes for demanding mixing applications.

-

Available in abrasion-resistant and corrosion-resistant materials.

-

Custom seal options for aggressive chemical environments.

GMX Series – Mid-Sized Tank Mixers

-

Perfect for tanks from 500 to 2,500 gallons.

-

Ideal for blending liquids, dispersing powders, or maintaining suspension.

Drum & Tote Mixers

-

Portable mixing solutions for small-batch chemical processing.

-

Easy to set up and move between containers, reducing downtime.

Why Choose Dynamix?

-

Engineering Expertise: Every mixer is designed based on fluid properties, tank geometry, and desired mixing outcome.

-

Durability: Heavy-duty shafts, impellers, and seals stand up to abrasive slurries and corrosive chemicals.

-

Versatility: Solutions for blending, emulsifying, suspension, and heat transfer applications.

VIDEO: Integrated Tote Mixer (ITM) with 4 Blade Collapsible Impeller – For IBC Tote Mixers

Amtrol: Advanced Industrial Tank Solutions

For decades, Amtrol has been a trusted name in pressure and storage tank manufacturing. Known for innovation and quality, Amtrol offers tanks designed to safely store and regulate fluids under pressure—an essential component in many chemical processing systems.

For decades, Amtrol has been a trusted name in pressure and storage tank manufacturing. Known for innovation and quality, Amtrol offers tanks designed to safely store and regulate fluids under pressure—an essential component in many chemical processing systems.

Key Product Lines:

Well-X-Trol® Series

-

Industry-leading well tanks with pressure ratings up to 150 psig.

-

Antimicrobial liners for cleaner fluid storage.

-

Welded steel construction for maximum durability.

-

Available in a variety of sizes to fit any application.

Therm-X-Trol® Expansion Tanks

-

Designed to control pressure in closed water heating and cooling systems.

-

Protects equipment and piping from thermal expansion damage.

-

Pre-charged and factory-tested for reliability.

Extrol® Expansion Tanks

-

Helps maintain safe system pressures by absorbing expansion water.

-

Prevents frequent relief valve operation and potential system damage.

-

Rugged steel shell construction with corrosion-resistant liner.

-

Factory pre-charged to minimize installation time.

Benefits for Chemical Applications:

-

Corrosion Resistance: Tanks are built to handle harsh chemicals and extreme conditions.

-

Pressure Stability: Maintains consistent pressure for safe and efficient operation.

-

Long Service Life: Engineered for years of maintenance-free performance.

Matching Tanks & Mixers to Your Chemical Process

Choosing the right combination of tank and mixer is critical for achieving the best results in chemical processing. Factors to consider include:

-

Chemical Compatibility: Ensure materials used in construction won’t react with your chemicals.

-

Mixing Intensity: Different reactions require varying levels of agitation—from gentle blending to high-shear mixing.

-

Tank Geometry: The shape and size of your tank influence mixer selection and impeller design.

-

Temperature & Pressure Requirements: Expansion tanks or insulated vessels may be necessary for high-temp or high-pressure applications.

By working with Kerr Pump & Supply, you gain access to experts who will evaluate your needs and recommend the ideal equipment combination.

Industries We Serve

Our ProQuip mixers, Dynamix agitators, and Amtrol tanks are trusted across a wide range of industries:

Paints & coatings – Pigment dispersion and viscosity control.

Chemical manufacturing – Blending raw chemicals, maintaining homogeneity, preventing sedimentation.

Pharmaceuticals – Sanitary mixing for active ingredients and suspensions.

Water & wastewater treatment – Coagulation, flocculation, and pH adjustment.

Food & beverage – Mixing flavorings, stabilizers, and emulsions.

Mining & minerals – Slurry handling, solids suspension, and reagent mixing.

Why Choose Kerr Pump & Supply?

We don’t just sell equipment—we partner with you to find the most effective solution for your process. Our team offers:

Custom configurations – We can adapt equipment for unique challenges, including hazardous environments.

Application expertise – Decades of experience with mixing and tank solutions.

Product selection assistance – Matching the right ProQuip, Dynamix, or Amtrol product to your needs.

Aftermarket support – Maintenance, repairs, and replacement parts.

Take the Next Step in Optimizing Your Chemical Process

If you’re ready to upgrade your chemical processing operations with industrial tanks and mixers that deliver superior performance and reliability, Kerr Pump & Supply is here to help.

Start exploring our solutions today:

From chemical mixing precision to safe, efficient storage, we have the expertise and equipment to keep your process running at peak performance. Contact us today for your chemical process solutions.

Additional Resources:

Reynolds Number for Industrial Mixing calculations