Vacuum Pumps

Kerr specializes in vacuum pumps for a variety of applications. We can assist you in sizing and selection, as well as vacuum pump rentals. Here are some of our more popular types of vacuum pumps and systems.

Oil Sealed Rotary Vane Vacuum Pumps

A rotary vane vacuum pump has an eccentrically installed rotor and vanes that divides the working chamber into two separate compartments with different volumes. As the rotor turns, gas flows into the enlarging suction chamber until it is sealed off by the second vane. The outlet valve is oil sealed. When the valve is open, a small amount of the oil goes into the suction chamber. The oil both lubricates and seals the vanes against the housing.

Rotary Claw Vacuum Pumps

Rotary Claw vacuum pumps use two claw shaped rotors turn in opposite directions inside the housing. The shape of the claw rotors causes the air or gas to be sucked in, compressed and then discharged. The rotors do not come in contact with each other or the cylinder they are in. The tight clearances optimize the internal seal and provide a consistently high pumping speed. Claw vacuum pumps are best suited to use with frequency controlled drives.

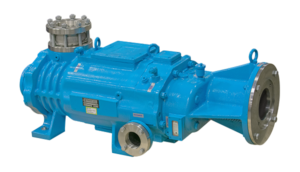

Dry Rotary Screw Vacuum Pumps

Dry screw vacuum pumps operate with two screw rotors rotating in opposite directions. This traps the medium to be pumped between the cylinder and the screw chambers and transports it to the gas discharge. The screw design results in lower electric energy consumption. It also results in a lower heat load of the compressed gas.

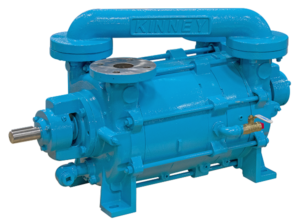

Liquid Ring Vacuum Pumps

Liquid Ring Vacuum Pumps use rotating positive displacement technology to provide process vacuum in industrial applications. They are similar to a rotary vane pump however they use liquid such as water or oil under pressure as a seal. They are low friction as the only moving part is the rotor. They are powered by a motor and are typically offered in single or multi stage.

Piston Vacuum Pumps

Piston Pumps are perfect for high viscosity liquids. They are highly efficient, offer higher pressure, and handle a wide range of materials. Piston Vacuum Pumps generate vacuum and compression to transfer gas through the movement of the piston sealed against a cylinder. The piston is connected to the crankshaft via a connecting rod. As the crankshaft rotates, the piston is pushed back-and-forth within the cylinder.

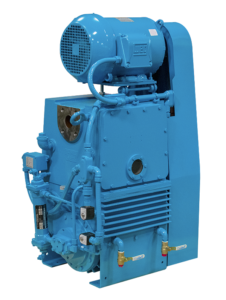

Vacuum Systems

We ensure optimum performance by considering process variables, specific measurements, special legislative requirements and environmental factors such as local climate during the design process of every system. Combining the correct product selection with the most suitable operating principles and construction materials optimizes other important characteristics such as energy efficiency and longevity.

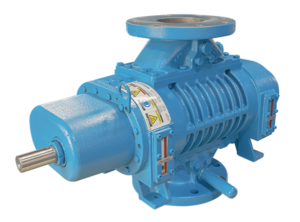

Positive Displacement Vacuum Boosters

Vacuum boosters are used to “supercharge” vacuum pumps to greatly extend pump performance. This allows for much faster pumping speeds and deeper vacuum pressure levels.

Vacuum Boosters, installed upstream of a primary pump, discharge to atmospheric pressure.

Vacuum Pumps are utilized in the manufacture of chemicals, petrochemicals, plastics, semiconductors, wood composites as well as food processing, vacuum furnace applications and many other general applications in industry use.

Vacuum Booster Skids

Kerr will also build Vacuum Booster Skids custom designed to meet your application specifications. Engineered vacuum systems with boosters are multi-stage systems that include one or more vacuum booster pumps and a primary pump.

Choosing the Right Industrial Vacuum Pump

How do you choose the right industrial Vacuum Pump ?

The answer lies in adequately defining your application’s needs in terms of several factors. Ask yourself these questions.

What technology type fits your application best?

Does your application require a lubricated or dry pump?

What chemical resistance is needed?

What are the range of flow rates required?

What pressure level ranges are best?

Are there specific motor requirements?

What is your annual operating and maintenance cost budget?

What is your capital budget for this purchase?

Here we provide three vacuum pump type comparisons on several vacuum pump manufacturers.

Download the Liquid Ring Vacuum Pump comparisons – MD-Kinney A Series to SIHI (Flowserve/Sterling), Gardner Denver (Nash/Rietschle), Traviani, and Dekker/Titan.

Download the Dry Claw Vacuum Pump comparisons – Kinney KVC, Busch Mink, Leybold, Atlas Copco, Edwards, and Airtech.

Download the Rotary Vane Vacuum Pump comparisons – Kinney KVO and KVC, Busch R5, Airtech L-series, Leybold Sogevac, Becker U-series, Republic and Edwards E-series.

Vacuum Pump Manufacturers that Kerr offers:

- Anest Iwata for dry scroll vacuum pumps

- MD-Kinney (formerly Tuthill) for vacuum pumps and boosters

- TMS Vacuum Pump

- Champion Air Compressors/ Div. of Gardner Denver for reciprocating, rotary screw and rotary vane

- Corken for Compressor pumps

- Hoffman and Lamson Engineered Vacuum Systems

- Republic Manufacturing for Dry Vane vacuum pumps

We can also help you find replacement pumps and parts for:

- Busch

- Becker

- Leybold

- Nash

- Atlas Copco