Industrial Vacuum Pump Repair Services for Fast, Reliable Performance

If your system relies on vacuum performance, even a small issue can lead to lost production, quality problems, and costly downtime. Professional industrial vacuum pump repair and maintenance restores your equipment to peak efficiency — often at a fraction of the cost of replacement.

This guide explains when to repair your vacuum pump, what to expect from a professional repair process, and why working with an experienced provider like Kerr Pump & Supply helps protect your operation.

When is Vacuum Pump Repair Needed?

Industrial vacuum pumps operate in demanding environments — handling heat, contamination, continuous operation, and heavy loads. Over time, wear and internal damage can reduce performance. Don’t ignore the early signs that your vacuum pump needs maintenance.

Common Signs You Need Vacuum Pump Repair or Maintenance

- Loss of vacuum level or slow pump-down times

- Excessive noise or vibration

- Overheating or high operating temperatures

- Oil contamination or leaks

- Increased energy consumption

- Frequent system shutdowns or alarms

Ignoring these symptoms can lead to catastrophic failure and unplanned downtime. Early vacuum pump service and repair keeps your system running efficiently and extends equipment life.

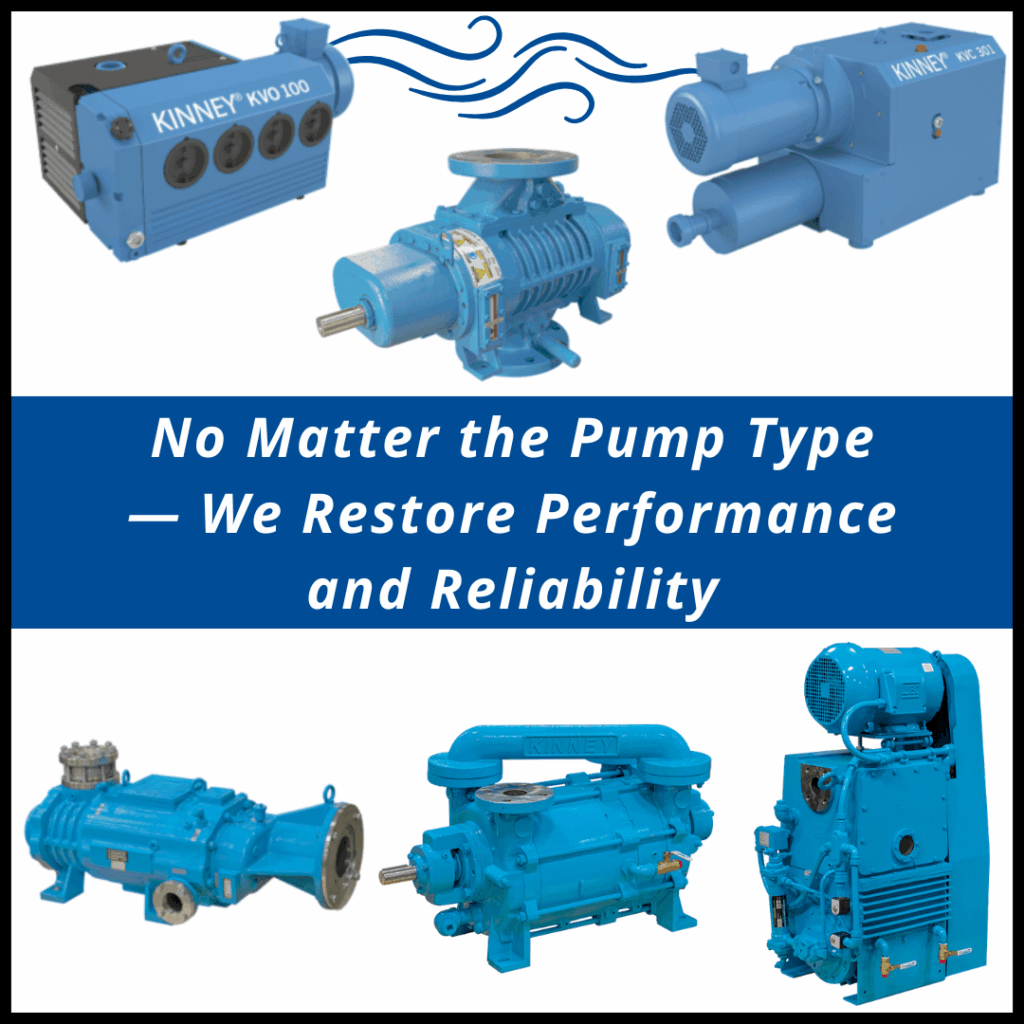

Types of Vacuum Pumps We Repair

Kerr Pump services a wide range of industrial vacuum pump technologies, including:

- Rotary vane vacuum pumps

- Liquid ring vacuum pumps

- Dry claw vacuum pumps

- Rotary lobe and blower vacuum systems

- Oil-sealed and oil-free vacuum pumps

Whether your pump is used in manufacturing, food processing, wastewater, chemical processing, or power generation, our technicians are trained to diagnose and restore performance.

Vacuum Pump Repair for Major Brands

Our technicians provide vacuum pump rebuild and repair for many leading manufacturers, including:

- Corken

- Gardner Denver

- Hoffman and Lamson

- TMS Vacuum Pump

- MD-Kinney

- And other major industrial vacuum pump brands

OEM-quality parts and proven repair procedures ensure reliable performance after service.

Vacuum Pump Repair Near You – Michigan Service Area

If you’re searching for vacuum pump repair near you, Kerr Pump & Supply provides fast, reliable service throughout Michigan and Ohio.

We offer shop repair, field service, vacuum pump rentals and emergency support to keep your operation running with minimal disruption.

Local service improves turnaround time and reduces transportation delays.

Benefits of Professional Vacuum Pump Repair

Working with an experienced vacuum pump service provider delivers measurable value:

- Restore original performance and efficiency

- Reduce energy consumption

- Extend equipment life

- Prevent unplanned downtime

- Lower total cost compared to replacement

- Receive documented inspection and testing reports

Kerr Pump also offers preventative maintenance programs to help avoid future failures.

Repair vs. Replace: How to Decide

Vacuum pump repair is often the best option when:

- The pump housing and major components are intact

- Repair cost is significantly lower than replacement

- Downtime must be minimized

- OEM performance can be restored

If replacement is more economical, Kerr provides expert guidance and access to industry-leading vacuum pump manufacturers. We sell industrial vacuum pumps used in a variety of industrial, medical, and chemical applications. With our broad range of sizes and technologies, we can help you find the correct vacuum pump for your process. Plus we deliver within 24 hours within a 50 mile radius of Kerr.

Industries We Serve

Our vacuum pump repair services support critical operations in:

- Manufacturing

- Automotive

- Chemical processing

- Food & beverage

- Wastewater treatment

- Power generation

- Pulp & paper

No matter the application, our goal is the same: maximize uptime and system reliability.

Preventative Vacuum Pump Maintenance: The Key to Avoiding Failure

Regular service helps prevent costly breakdowns.

Recommended practices:

- Routine oil analysis and changes

- Seal and bearing inspections

- Performance testing

- Vibration monitoring

- Scheduled overhauls

A preventative maintenance program can reduce emergency repairs and extend pump life by years.

We also recommend Kerr-Lube Vacuum Pump Oil, our specialized vacuum pump oil designed for long life under severe conditions.

The Kerr Vacuum Pump Repair Process (Step-by-Step)

Our structured repair process ensures accuracy, transparency, and reliable results.

1. Initial Contact & Pump Information

The customer contacts Kerr Pump & Supply with pump details and operating concerns.

2. RGA Issued

An RGA (Return Goods Authorization) is issued to track the equipment throughout the repair process.

3. Receiving & Job Creation

Once the pump arrives:

- Shipping & receiving logs the unit

- The pump is transferred to the repair department

- A quote number and serialized manufacturing number are generated

4. Complete Inspection & Tear Down

A qualified technician:

- Disassembles the pump

- Documents internal condition

- Identifies worn or damaged components

- Provides required parts, labor, and repair recommendations

- Captures inspection photos from start to finish

5. Detailed Repair Report & Quote

The repair manager compiles a professional report including:

- Inspection photos

- Failure analysis

- Recommended repairs

- Replacement options (if applicable)

- Total repair cost

The report is sent to the customer.

6. Customer Approval & Scheduling

Once customer decides to repair or replace the unit:

- Order confirmation is issued

- Estimated ship date provided based on parts availability

- Parts and paperwork released to the technician

7. Precision Rebuild

The pump is rebuilt using specified parts and procedures to restore original performance.

8. Performance Testing

Every repaired vacuum pump undergoes a 4-hour operational test to verify:

- Vacuum performance

- Mechanical stability

- Proper operation under load

A test report is generated and shared with the customer.

9. Final Preparation & Return

Before shipment:

- Pump is painted

- Mounted on a skid

- Carefully packaged and returned to the customer

Why Choose Kerr Pump & Supply for Vacuum Pump Repair?

- Factory-trained technicians

- Comprehensive inspection with photo documentation

- Full performance testing before shipment

- OEM-quality parts and repair procedures

- Fast turnaround and clear communication

- Repair, replacement, and system optimization expertise

When downtime isn’t an option, experience matters.

Ready to Schedule Vacuum Pump Repair?

If your vacuum pump isn’t performing as it should, don’t wait for a complete failure.

Contact Kerr Pump & Supply today for expert industrial vacuum pump repair, inspection, and service.

CONTACT USSources

Kerr Internal Vacuum Pump Repair Process

Kerr Pump & Supply – Industrial Pump Repair Services

Kerr Pump & Supply – Pump Repair Service Details

Kerr Pump & Supply – Vacuum Pump Products

Key Takeaways

- Vacuum Pump Repair Services restore equipment performance, preventing production loss and downtime.

- Signs of needed repair include loss of vacuum, excessive noise, overheating, and increased energy consumption.

- Kerr Pump & Supply offers a wide range of vacuum pump repair services for major brands and various pump types.

- Professional repair delivers benefits like restored efficiency, reduced energy costs, and extended equipment life.

- Regular maintenance and a structured repair process enhance reliability, ensuring pumps operate optimally.