Kerr Pump & Supply offers the Deragger pump monitoring system that will eradicate pump clogs in wastewater pumps. Deragger has significant advantages over Choppers or Grinders, which create particles that are passed through headworks screens and cause problems in treatment plant processes. Deragger does not. Deragger reverses the flow, dislodges the wipe from the impeller, then sends it along through the normal process.

The key feature of the Deragger+ low-voltage, electronic pump management system is real-time pump monitoring. The patented Deragger technology also can reduce wear and tear caused by unbalanced loads by monitoring the long-term condition of the pumps.

As a Deragger distributor, Kerr offers Deragger parts and an extensive service department that can assist with any pump system repair that is needed. Our service technicians are fully insured, certified and factory trained to ensure your satisfaction.

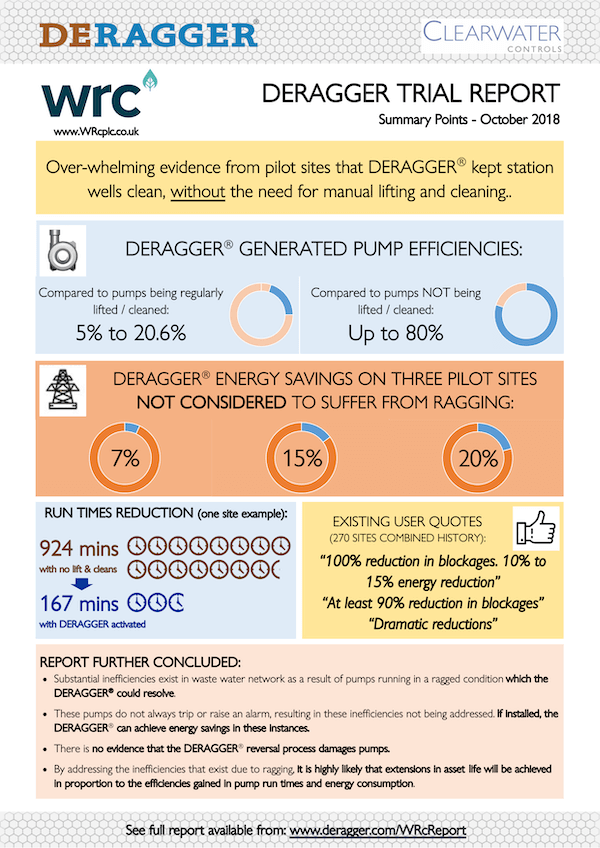

In independent testing, DeRagger kept station wells clean without the need for manual lifting and cleaning. See the tests results here.

Comparison to VFDs, PLC, VSD and Chopper

When you compare the results offered by the different technologies available on the market, DeRagger stands out. See for yourself in these comparison reports.

As a Deragger distributor, Kerr Pump & Supply offers a range of Deragger products.

Deraggger+ and Deragger Lite

The Deragger+ and Deragger Lite end pump ragging and improve efficiency. The DERAGGER+ constantly monitors the torque signature of a pump’s motor, and can dislodge and pass rags in Real Time should they become stuck on or inside the impeller/volute. This is achieved with a tuneable “clean cycle” involving a brief and unique series of forward and reverse motions of the impeller.

Deragger+ ends the time-consuming and costly process of manually lifting pumps to clear the rags, thus reducing downtime and pump repairs.

- Wealth of diagnostic information and pump data

- Typical payback in months

- Reduces operational callout costs

- Improves electrical efficiency by up to 48%, lowering carbon footprint

- Reduces pollution incidents

- Minimal interruption to ‘live’ sites

- No new kiosks, replacement panels or construction works

- Simple plug and play to any starter type

- Also includes multiple Mobile Apps to help protect your assets – motor protection, data logger, wet well clean, dry run protection, float switch backup, odor control, derived flow

Deragger Lite is a simpler anti-ragging device for those that do not need data logging or the additional applications provided with the Deragger+.

Deragger Pro Station Controller

The Deragger Pro station controller offers uninterrupted operation with comprehensive fault-finding diagnostics in an intelligent interface.

The DERAGGER PRO simplifies pump station control by combining the functions of the DERAGGER+ with a pump station controller. It provides a complete interface for the DERAGGER+ and other supported accessories required in pumping operations.

- reduces operational costs by ensuring the most energy-efficient pumps are used

- creates redundancy by spreading intelligence between multiple devices

- controls up to 16 pumps or motors in up to 16 different groups/wells

The DERAGGER PRO’s high-resolution color touchscreen uses gesture control for quick access to features like Derived Flow Metering (where level monitoring is used), Full Alarm Logging and Pump Station Trends.

Power Monitor

The power monitor combines motor protection, sensing and logging in one compact device.

- Smart technology combining power analyzer and data logger

- Easy integration by installing the small unit into existing or new panels

- Compatible with all starter types, VFDs etc.

- Easy-to-use keypad with USB connectivity and convenient SD Card data storage

Kerr Pump & Supply Deragger Case Studies

Tawas City, Michigan

- DERAGGER+ installed along with DERAGGER PRO.

- Monthly saving of between $1,200 and $3,600!

- Elimination of ragging problems.

- “We were coming to clean these pumps as often as three times a week, and we haven’t had to clean either a single time since installing the DERAGGERs!”

Union Township, Michigan

- Side-by-side comparison with self-reversing pump with integrated VFD.

- DERAGGER+ installed along with DERAGGER PRO.

- Elimination of ragging problems.

- “After trialing both…side by side, I prefer the PRO for its functionality, flexibility and great color touchscreen. It also costs a fraction of what a self-reversing pump would cost…It’s a no brainer!”

Deragger News Articles

Read our Municipal Sewer & Water article

Read our Treatment Plant Operator article

How to Stop Wastewater Pump Clogs

Improved Wastewater Pump Stations in Tawas City MI

Kerr Pump – Deragger YouTube Channel

(To see video choices, open playlist using the upper menu bars) ![]()

Let the Kerr Sales Engineersdesign the right solution for your application