During Kerr’s service process pump inspections, our customers benefit from our complete tear down and parts review that make the repair vs. replace decision simple. Here are some examples.

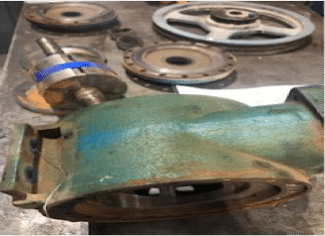

Blackmer Pump Service Example

The heads were removed and inspected. They are damaged from rotor contact and will require replacement.

The rotor and shaft were removed and inspected. There is runin on both ends of the rotor and damage at the bearing journals. A new rotor and shaft will be required.

The mechanical seals were removed and inspected. They are brittle and damaged. New mechanical seals will be required.

The cylinder was removed and inspected. It is scored and grooved and will require replacement.

Decision was made to replace this pump. The cost of the repair was going to be close to the cost of a new pump.

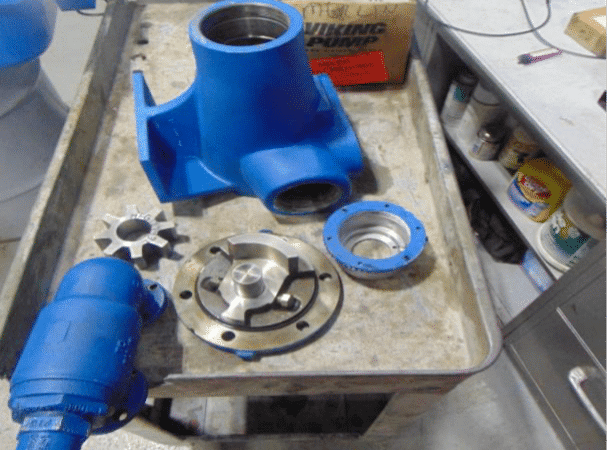

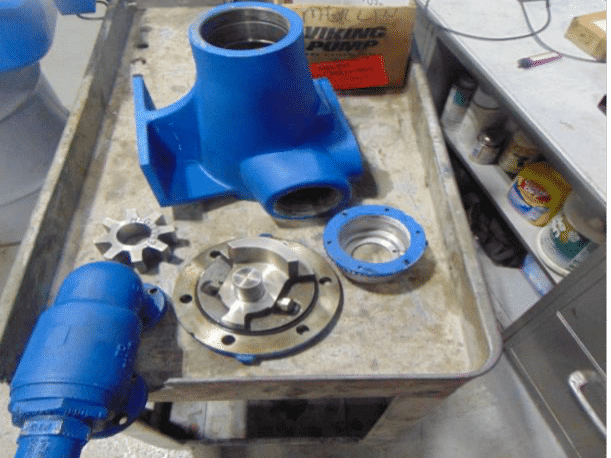

Viking Pump Service Example

The idler and head and pin were removed, inspected and measured. The idler bushing is broken in several pieces. We are recommending a new idler with tungsten/carbide bushing and a new head & tungsten carbide pin. This will prolong the life of the pump.

The rotor & shaft were removed, inspected and measured. The rotor & shaft are still within Viking specifications. They will be cleaned and reinstalled during the rebuild.

The mechanical seal was inspected and has some wear. A new mechanical seal will be installed during the rebuild.

The casing was removed, inspected and measured. It is still within Viking specifications.

The removable bearing housing was inspected and measured. It is still within Viking specifications. The housing will be cleaned and reinstalled with a new bearing during the rebuild.

The relief was removed and inspected. No discrepancies were noted. The relief valve will be cleaned and reinstalled during the rebuild.

Decision was made to rebuild.

Corken Compressor Rebuild Example

The crankshaft was inspected, and the connecting rod journals were measured. Since it is still within Corken specifications, it be reinstalled with new main bearings during the rebuild.

The connecting rod and bearing inserts were inspected. The inserts have even wear, but are replaced as a normal wear item. New inserts will be installed during the rebuild.

The wrist pin bushings were inspected and have normal wear present. New bushings will be installed during the rebuild.

The crossheads and wristpins were inspected and measured. The crosshead and shaft are still within Corken specifications and will be reinstalled during the rebuild. The wrist pins will be replaced.

The crosshead cylinders were inspected and measured. They are still within Corken specifications.

The pistons were inspected and measured. There is damage to one piston platform which will be replaced. The pistons will be cleaned and reinstalled with new piston rings during the rebuild.

The piston cylinders were inspected and measured. They are still within Corken specifications. The cylinders will be honed prior to reassembly.

The suction and discharge valve assemblies were inspected, and they were intact. New valve assemblies with gaskets will be installed during the rebuild.

The oil pump was removed and inspected. There is some wear on the pump shaft adapter, spring and gear. A new oil pump assembly will be installed during the rebuild.

The pump was repaired, painted and returned to our customer.

Get more information on Pump Repairs, or contact Kerr directly to arrange for a pump repair quote.