Viking Pumps are used throughout the chemical processing industry, from refineries and gas processing plants to basic chemical plants to polymer processing to end use product manufacturing. The chemical industry encompasses such a broad range of fluids and processes, that just about every type of Viking pump made is used in one application or another.

For basic chemical manufacturing, the XPD 676 Series, Universal Seal series and Universal Mag Drive series pumps are used most often.

Where temperature control is required or materials are solid at ambient temperatures, the Jacketed Universal Seal series are used.

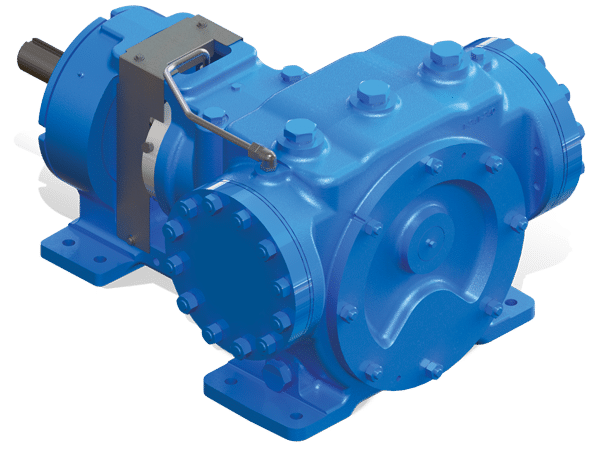

XPD 676 Series (API 676 – meets requirements for rotary positive displacement process pumps and pump units for use in the petroleum, petrochemical, and gas industry services.)

XPD 676 Series (API 676 – meets requirements for rotary positive displacement process pumps and pump units for use in the petroleum, petrochemical, and gas industry services.)

Max. Capacity: to 1,100 GPM (250 M3/Hr)

Max. Pressure: 200 PSI (14 BAR) Higher Pressure Available with Factory Approval

Max. Viscosity: to 35,000 SSU (7,700 cSt)

Higher Viscosity Available with Special Construction

Temperature Range: -20°F to +400°F (-29°C to +205°C) Broader Temperature Range Available with Special Construction

Universal Mag Drive – Dimensionally Interchangeable Sealless Drive Pumps for Crucial Liquid Containment Applications

Universal Mag Drive – Dimensionally Interchangeable Sealless Drive Pumps for Crucial Liquid Containment Applications

Max. Capacity: 500 GPM (115 M³/hr)

Max. Pressure: 200 PSI (14 BAR)

Max. Viscosity: 250,000 SSU (55,000 cSt)

Temperature Range: -120°F to +500°F (-85°C to +260°C)

Jacketed Universal Seal – Available in cast iron, ductile iron, steel, stainless steel to allow broad temperature range

and chemical compatibility.

Jacketed Universal Seal – Available in cast iron, ductile iron, steel, stainless steel to allow broad temperature range

and chemical compatibility.

Max. Capacity: 1,600 GPM (365 M³/hr)

Max. Pressure: 200 PSI (14 BAR)

Max. Viscosity: 2,000,000 SSU (440,000 cSt)

Temperature Range: -120°F to +800°F (-85°C to +430°C)