Ever wonder how toothpaste is made? Since it’s part of a daily routine, it is highly likely that you don’t! But since Kerr Pump & Supply provides some of the equipment, we think it’s interesting and thought we would share this article written by Proquip, one of our manufacturers who makes Process Tank Agitators & Mixers.

Ever wonder how toothpaste is made? Since it’s part of a daily routine, it is highly likely that you don’t! But since Kerr Pump & Supply provides some of the equipment, we think it’s interesting and thought we would share this article written by Proquip, one of our manufacturers who makes Process Tank Agitators & Mixers.

Toothpaste is big business for the corporate conglomerates that produce most of the world’s toothpaste (e.g., Colgate Palmolive, Proctor and Gamble, Unilever). Americans alone buy over 14 million gallons of toothpaste every year (Source: Acceledent). For a little perspective, that’s roughly equal to 175,000 bathtubs of the creamy mint stuff.

History of Toothpaste

Products that resemble modern toothpaste first appeared in the mid-nineteenth century. Prior to their introduction, people used a variety of methods and materials to clean their teeth – if they cleaned them at all. Many practices were unpleasant (e.g., ground fish bones – Chinese; sand and pumice – Middle Age Arabs). Some were toxic (e.g., green lead, verdigris, incense – Ancient Egyptians; acid – Europeans). Others were quite ordinary (e.g., table salt).

Most crude methods of cleaning teeth came to end when Dr. Washington Wentworth Sheffield, a dental surgeon and chemist from Connecticut, invented, manufactured and marketed the first toothpaste in 1850. Sheffield’s company also claimed to be the first to put toothpaste in tubes – it was originally packaged in jars – after Dr. Sheffield’s son traveled to Paris. On the trip, he noticed collapsible metal paint tubes and concluded the tubes could also be used for toothpaste.

Several other companies claimed they, not Sheffield, were the first to put toothpaste in a tube. The Colgate-Palmolive Company asserted it sold the first toothpaste in a collapsible tube in 1896. Johnson and Johnson made claims it was the first to put toothpaste in tubes around 1900.

Regardless of who put toothpaste in a tube for the first time (the world may never know), most toothpaste-related innovations since have focused on the product not the container. Some of the more significant innovations include:

1960s: addition of fluoride to help reduce tooth decay, gel-based formulas

1980s: tartar control formulas, pump/standup tubes

1990s: sensitive teeth formulas, addition of decorative elements (stripes, sparkles, etc.)

Toothpaste Ingredients

Fortunately, the days of toothpaste made of ground fish bones and acid are long gone. The ingredients used in today’s toothpastes perform and taste far better than their ancient counterparts.

Most modern toothpastes contain the following ingredients:

- Water

- Abrasives (e.g., softened silica, chalk, baking soda)

- Sudsers (e.g., sodium lauryl sulfate, sodium lauryl sulfoacetate, dioctyl sodium sulfosuccinate)

- Humectants (e.g., sorbitol, glycerin, propylene glycol) which retain paste form, contribute to mouth feel and add sweetness

- Flavors (typically mint)

- Sweeteners (typically Saccharin)

- Fluorides

- Whiteners

- Preservatives (typically p-hydrozybenzoate)

- Binders (e.g., karaya gum, bentonite, sodium alginate, carrageenan) which provide thickening and prevent separation of solid and liquid ingredients, control foam production, rate of flavor release and product dispersal, as well as appearance on the toothbrush, and toothbrush rinsability.

Toothpaste Manufacturing and Packaging Process

The process for making toothpaste is relatively straight forward. Toothpaste ingredients are weighed to ensure the correct proportions. Ingredients are then mixed together in a stainless-steel vessel (water and the humectant is usually done first). Process temperature and humidity are watched closely to ensure proper mixing. A typical batch is equivalent to 10,000 four-ounce (118 ml) tubes.

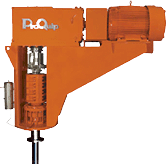

Major toothpaste manufacturers use ProQuip tank agitators in their production process. A typical agitator configuration for production of standard toothpaste is a center-mounted, top-entry agitator with impellers designed for high viscosity processes. ProQuip agitators are also used to manufacture specialty toothpaste formulas including those with suspended sparkling particles.

Major toothpaste manufacturers use ProQuip tank agitators in their production process. A typical agitator configuration for production of standard toothpaste is a center-mounted, top-entry agitator with impellers designed for high viscosity processes. ProQuip agitators are also used to manufacture specialty toothpaste formulas including those with suspended sparkling particles.

After the ingredients are mixed together, the finished toothpaste is sent to a high-speed filling machine where a pump fills each tube through its open bottom. After the tube is filled, the end is sealed (or crimped) closed.

Filled and crimped tubes are inserted into individual retail boxes. The boxes are then packed into master cartons and shipped to warehouses, distribution centers and stores.