Industrial vacuum pumps are available in a variety of configurations for various applications and industries.

- Automotive

- Aviation & Aerospace

- Chemical

- Construction & Transportation

- Energy and Power

- Food and Beverage

- Pharmaceutical

- Plastics

- Water and Wastewater

Automotive Vacuum Pumps

Hydraulic Brake Systems

One of the unheralded but very necessary applications for vacuum pumps is the pre-evacuation and leak testing of hydraulic brake systems in new cars.

A typical brake filling machine manufactured by one of our OEM’s consists of three vacuum pumps, with one dedicated to keeping the brake fluid deaerated and free of moisture and the other two used for evacuation of the vehicle’s brake system, either with both pumping or one active and the other backup; a reservoir containing deaerated brake fluid for filling using hydraulic/pneumatic driven cylinders; PLC control and diagnostic system with operator interface; vacuum and pressure sensors; and quick disconnect adaptor that connects quickly to the master cylinder and is used for both evacuation and brake filling.

A typical brake filling machine manufactured by one of our OEM’s consists of three vacuum pumps, with one dedicated to keeping the brake fluid deaerated and free of moisture and the other two used for evacuation of the vehicle’s brake system, either with both pumping or one active and the other backup; a reservoir containing deaerated brake fluid for filling using hydraulic/pneumatic driven cylinders; PLC control and diagnostic system with operator interface; vacuum and pressure sensors; and quick disconnect adaptor that connects quickly to the master cylinder and is used for both evacuation and brake filling.

The vacuum pumps required need to be robust and reliable and have the ability of repetitive performance without degradation while still being compatible with brake fluid for multiple evacuations which can vary depending upon braking systems from 40 to 60 vehicles per hour per machine.

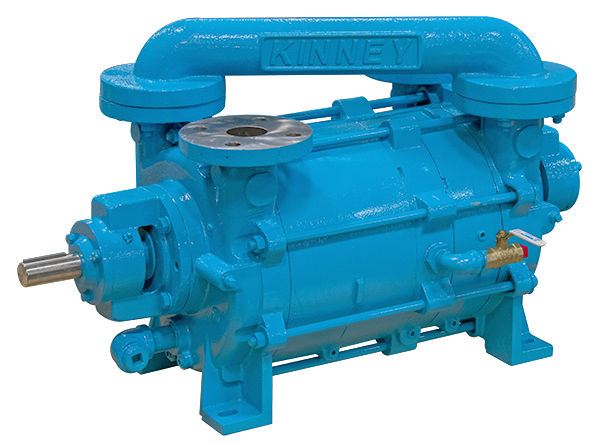

MD-Kinney’s KC series of small two-stage rotary piston pumps meet these requirements with the KC15 being a particular favorite of OEM’s for brake filling machines. The KC pumps are ruggedly constructed with all cast iron rotary internals and can operate using a brake fluid compatible elastomer and lubricant such as UCON LB-300x which is a polyalkylene glycol (PAG) that will mix with the brake fluid should the brake fluid enter the pump or pump fluid enter the brake system due to an unlikely system upset that circumvents protective safeties. The KC15s, like other installed components, are normally provided unpainted due to the paint stripping nature of the brake fluid. MD-Kinney works with OEM’s to meet their pumping requirements with rugged, first-class pumping equipment that is superbly compatible with the process.

Aviation & Aerospace Vacuum Pumps

Altitude Simulation

MD-Kinney’s vacuum booster systems are actively in use at a variety of aerospace facilities responsible for performing developme nt and certification tests for altitude simulation. Simulations are typically performed in test chambers equipped with element heaters that can imitate launch pressure decay, on orbit cold-soak, and re-entry heating and pressure elements to assess the performance of an aircraft before being qualified to take flight. A booster system is utilized in the test chamber in order to simulate the near outer space atmosphere during the heat test.

nt and certification tests for altitude simulation. Simulations are typically performed in test chambers equipped with element heaters that can imitate launch pressure decay, on orbit cold-soak, and re-entry heating and pressure elements to assess the performance of an aircraft before being qualified to take flight. A booster system is utilized in the test chamber in order to simulate the near outer space atmosphere during the heat test.

Brake Pads

MD-Kinney is proud to design and manufacture the vacuum systems that are used in the production of aircraft carbon brake pads. Utilized on commercial and military aircraft, brake pads are essential to function and need to be able to sustain the high temperatures that come from the conversion of the plane’s kinetic energy into heat. Carbon brake pad production begins with carbon fiber that goes through a carbonization process at high temperatures in an inert gas atmosphere to eliminate excess gases. The fibers are then placed in a vacuum furnace using chemical vapor disposition and chemical vapor infiltration to repair any voids and add density to the material. Vacuum systems are essential in this process because of their ability to handle the various hydrocarbons, carbon dusts, and tar carryover that results.

Vacuum Furnace

Vacuum heat-treating furnaces are essential in the production of aluminum alloys used in the structure of aircrafts and jet engine blade coatings. Because aircrafts need to function at optimum levels dependent on the environmental conditions, a plane’s life relies on the structure of its alloy that is produced in the vacuum furnace. In the aerospace industry, heat treatment is performed to improve the overall life and functionality of components and enhance their resistance to wear and corrosion. The vacuum furnace is used to heat metals to extremely high temperatures while achieving high consistency and low contamination of gases, blocking oxygen and reducing rapid oxidation.

Chemical Vacuum Pumps

Distillation

Distillation is the thermal process of separating different solvents varying in temperature, pressure, and composition from a liquid mixture by selective boiling and condensation in order to increase the condensation of those selected components. In order to separate the solvents from each other, vapor has to be removed from a boiling  liquid mixture and recondensed after evaporation. Vacuum pumps are ideal for the removal of non-condensable water and light solvents by providing pressure variation to allow for further separation.

liquid mixture and recondensed after evaporation. Vacuum pumps are ideal for the removal of non-condensable water and light solvents by providing pressure variation to allow for further separation.

Evaporation

In the pharmaceutical industry, the evaporation process is essential in eliminating excess moisture in order to make products easier to handle, preserve long-term activity, and improve the stability of enzymes. MD-Kinney’s SDV systems have been used within many film evaporation applications in the production of high-performance medical grade silicones such as those used in implants, tubing for catheters, drug delivery, and skincare cosmetics such as moisturizers, anti-aging creams, sun care, and anti-wrinkle formulas.

Pneumatic Conveying

The use of positive displacement blowers in pneumatic conveying provides efficient transfer of dry bulk material from point to point at varying pressures and vacuum levels. Pneumatic conveying is achieved by creating a pressure differential along a pipeline and using the air that moves toward the area of lower pressure to move the dry bulk material. This process can be accomplished with a vacuum inducer or by injecting compressed air into one end of the pipeline. Unlike other air moving technologies, MD-Kinney’s rotary positive displacement design provides constant flow regardless of pressure. Our positive displacement blowers have been successful in pneumatic conveying applications in a variety of industries for over 60 years.

Gas Filling

The use of bottled cylinders containing compressed gas is present in several industrial sectors including medical and healthcare, food and beverage, pharmaceutical, and science and research. Many of these cylinders, particularly the highly purified gases, require a pre-evacuation stage to ensure removal of residual gases and possible contaminants before being refilled. In standard uses, gas cylinders are not completely emptied in order to avoid drawing in contaminants such as air or water vapor that could cause additional impurities or lead to issues such as corrosion or creating explosive mixtures. Vacuum pumps are commonly found in gas refilling stations to accomplish this pre-evacuation stage.

Solvent Recovery

Vacuum systems are used to pump solvent vapors in many pharmaceutical applications wherever excess solvents must be removed such as in processes involving drying, distilling, synthesis of compounds, purification, and cleaning. Many organic solvents need to be recovered due to their toxicity, flammability, or environmental impact, and dry vacuum pumping systems are the ideal solution due to having no internal sealing liquid that could contaminate the process. Solvent vapors are passed through the dry vacuum system and condensed at the exhaust that provides a closed-loop for containing and recovery.

Vapor Recovery

Vapor recovery units are often incorporated into pipeline systems in order to remove harmful contaminants from crude oil products, improving purity levels and preventing the release of toxic pollutants into the environment. Local environmental protection authorities have established guidelines for the process and storage of gas and chemical products, placing a heightened response on industries to create sustainable ways to lessen vapor pressure in tanks and prevent emission release. A blower is often used in vapor recovery to boost pressure in a pipeline and push the gas into another process where it can be reused, or sent to a natural gas compressor.

Construction & Transportation Vacuum Pumps

Impregnation Systems

Vacuum Pressure Impregnation (VPI) uses vacuum pressure to seal cavities in various materials such as in castings that need to be used in a leak-free application, smoothing surfaces for improved machinability, electrical windings of motors that require sealing from moisture, and infusing wood with resins to protect from exposure to the elements.  The VPI process requires using a vacuum-tight chamber and pulling a vacuum to lower levels in order to remove both air and moisture from all the cavities that could trap gas or vapor.

The VPI process requires using a vacuum-tight chamber and pulling a vacuum to lower levels in order to remove both air and moisture from all the cavities that could trap gas or vapor.

Dry Bulk Transfer

Transport blowers have been used throughout the dry bulk transfer application for years, being relied on to move dry bulk product such as cement, powders, crushed limestone, sand, and other granular materials from the truck to the customer end point. Blowers are required to be rugged and durable in order to withstand its exposure to the element while mounted on a truck. M-D Pneumatics transport blowers are commonly seen mounted on tractor frame rails and are driven by transmission mounted power take-offs.

Vacuum Pumps for Energy and Power

Distillation

Distillation is the thermal process of separating different solvents varying in temperature, pressure, and composition from a liquid mixture by selective boiling and condensation in order to increase the condensation of those selected components. In order to separate the solvents from each other, vapor has to be removed from a boiling liquid mixture and recondensed after evaporation. Vacuum pumps are ideal for the removal of non-condensable water and light solvents by providing pressure variation to allow for further  separation.

separation.

Vapor Recovery

Vapor recovery units are often incorporated into pipeline systems in order to remove harmful contaminants from crude oil products, improving purity levels and preventing the release of toxic pollutants into the environment. Local environmental protection authorities have established guidelines for the process and storage of gas and chemical products, placing heightened response on industries to create sustainable ways to lessen vapor pressure in tanks and prevent emission release. A blower is often used in vapor recovery to boost pressure in a pipeline and push the gas into another process where it can be reused, or sent to a natural gas compressor.

Landfill Gas

M-D Pneumatics blowers are becoming more commonly used in landfill gas applications. The cost of energy continues to rise and the means by which to produce it are becoming more expensive and coming under increased scrutiny for various reasons including the amount of pollution released in the process. At the same time, municipal landfills are exceeding capacity and uses are being made for the decomposing organic waste. One of those uses is converting landfill gas to energy. As the waste in a landfill decomposes, a form of natural gas is created, commonly referred to as Landfill Gas, (LFG). LFG is a mixture of methane and carbon dioxide along with some other non-organic compounds. The gas is gathered for various reasons, primarily for odor control and to prevent it from going into the atmosphere. During this process, blowers are used to help collect and move the gas. Generally the gas is gathered under a slight vacuum and discharged at around 5 psig into a header that feeds the landfill gas as a fuel to a special natural gas engine that drives the generators which actually convert it to electricity where the gas is used to power the landfill operations, sold to a local utility provider or even used to power certain types of vehicles.

Solar Power

1ST GENERATION CELL (CRYSTALLINE SILICON)

Producing Poly silicon Solar grade silicon is produced in the reactors using metallurgical grade silicon by means of chemical vapor deposition (CVD) process. The process introduces silane gas with high temperature polysilicon rods inside a cooled bell jar. The silicon contained in the gas will deposit on the heated rods, which gradually grow until the desired diameter has been reached. The usage of a vacuum system is to evacuate the reactors prior to a chemical reaction taking place. Vacuum operating level for this application is anywhere from 0.5 to 1 Torr. Kinney® can supply either booster/piston systems, booster/vane systems or booster/dry pumping systems.

2ND GENERATION CELL (THIN FILM)

Many thin-film devices are based on amorphous silicon alloys. Other thin-film devices are usually poly-crystalline materials. The fabrication of a thin-film solar cell involves depositing a layer of semiconductor material (such as amorphous silicon, copper indium gallium diselenide, or cadmium telluride) on a low-cost substrate, such as glass, metal, or plastic. Current deposition techniques can be broadly classified into physical vapor deposition (PVD), chemical vapor deposition (CVD), plasma enhanced chemical vapor deposition (PECVD) or some combination of them. Vacuum pumps will see toxic, corrosive, explosive, pyrophoric and light gases such as hydrogen, Silane, helium, sulfur hexafluoride (SF6), Nitrogen trifluoride (NF3), phosphine, Germane, Boron Trifluoride and many more depending on process and technology. In addition, vacuum pumping speeds and rapid chamber cycling are essential. Our two stage vacuum systems meet the above requirement. Our systems equipped with NEMA control panel to operate on/off the system as well as safety interlocks for the system such as high oil temperature and high gas discharge temperature. Inert gas purge controls also provided to suit the application.

Food & Beverage Vacuum Pumps

Pneumatic Conveying

The use of positive displacement blowers in pneumatic conveying provides efficient transfer of dry bulk material from point to point at varying pressures and vacuum levels. Pneumatic conveying is achieved by creating a pressure differential along a pipeline and using the air that moves toward the area of lower pressure to move the dry bulk material. This process can be accomplished with a vacuum inducer or by injecting compressed air into one end of the pipeline. Unlike other air moving technologies, M-D Pneumatics’s rotary positive displacement design provides constant flow regardless of pressure. Our positive displacement blowers have been successful in pneumatic  conveying applications in a variety of industries for over 60 years.

conveying applications in a variety of industries for over 60 years.

Freeze Drying

The freeze-drying process has seen heightened demand due to an increase in the need for dry foods with extended shelf life, or to make perishable materials more convenient for transport. Freeze-drying is a low temperature dehydration process performed under a vacuum that involves freezing the material, placing under a deep vacuum to reduce the pressure, and adding heat to allow the frozen water to sublimate. To achieve a successful freeze-drying process, it should be repeatable with well-defined temperatures, pressure, and time parameters for each step.

Maple Sap Extraction

Production for maple syrup typically happens during the late winter months, as freezing nights and warmer days are needed in order to induce sap flow. With such a narrow timeframe to extract sap from the trees, maple sugar producers must make the most of their extraction process. Today’s maple sap extraction process has evolved to the use of plastic tubing and a liquid ring vacuum pump, allowing for an increase in production and ensuring the finished product arrives cold and clear to the sugarhouse.

Meat Processing

Kinney’s rotary vane vacuum pumps and liquid ring vacuum pumps can be found in a variety of applications within the meat processing industry including stuffing, packaging, mixing, and tumbling. Vacuums perform countless tasks in meat processing facilities including removing excess air out of products improving product color and texture (stuffing), providing a gas-tight package for lower shelf life (packaging), blending meats and spices for a more desirable texture (mixing), and opening tissue for a more uniform distribution of flavor (tumbling). Vacuums have also become more prevalent in the cooling process, conserving meat after it has been cooked in order to help kill pathogenic microorganisms that can cause toxins or spoil.

Sterilization

Sterilization is a process designed to remove or destroy all viable forms of microbial life. Ethylene oxide (EtO) treatment methods have been used for decades throughout the low-moisture food industries to safely eliminate pathogens such as salmonella and e-coli. Ethylene oxide is a toxic, flammable gas that breaks down microorganisms on a chemical level. EtO sterilization is often preferred for sterilizing temperature or moisture sensitive products and requires that they be preconditioned in a controlled environment of temperature and humidity. The effectiveness of this process relies four critical factors: gas concentration, humidity, temperature, and time. Kinney’s liquid ring vacuum pump has been a preferred solution in EtO sterilization due to its water sealing and ability to handle flammable gases.

Vacuum Packaging

The use of vacuum pumps in the packaging process is key to extending the shelf life of products. Vacuum pumps are responsible for evacuating air as well as removing water, vapor, fat, and granular materials before goods go to market. In the chamber packaging process, food is placed inside a vacuum bag and loaded into a packaging chamber where the air can be evacuated, and the bag heat sealed. Blowers can also be used in low vacuum applications for packaging and handling in order to filter impurities and dust.

Pharmaceutical Vacuum Pumps

Distillation

Distillation is the thermal process of separating different solvents varying in temperature, pressure, and composition from a liquid mixture by selective boiling and condensation in order to increase the condensation of those selected components. In order to separate the solvents from each other, vapor has to be removed from a boiling liquid mixture and recondensed after evaporation. Vacuum pumps are ideal for the removal of non-condensable water and light solvents by providing pressure variation to allow for further  separation.

separation.

Evaporation

In the pharmaceutical industry, the evaporation process is essential in eliminating excess moisture in order to make products easier to handle, preserve long-term activity, and improve the stability of enzymes. Kinney’s SDV systems have been used within many film evaporation applications in the production of high-performance medical grade silicones such as those used in implants, tubing for catheters, drug delivery, and skin care cosmetics such as moisturizers, anti-aging creams, sun care, and anti-wrinkle formulas.

Pharmaceutical

Vacuum pumps play a vital role in the pharmaceutical industry for the manufacturing of bulk drugs, intermediate products, and active pharmaceutical ingredients (APIs). The production of pharmaceutical products demands high-quality standards and processes, several of which require the need to operate under vacuum for separation without thermally degrading the end result. Vacuum pumps come into contact with solvents, vapors, and various gases in several pharmaceutical applications, requiring that they have reliable performance and durability. Kinney provides comprehensive engineering and product solutions to meet these demands.

Solvent Handling

Vacuum systems are used to pump solvent vapors in many pharmaceutical applications wherever excess solvents must be removed such as in processes involving drying, distilling, synthesis of compounds, purification, and cleaning. Many organic solvents need to be recovered due to their toxicity, flammability, or environmental impact, and dry vacuum pumping systems are the ideal solution due to having no internal sealing liquid that could contaminate the process. Solvent vapors are passed through the dry vacuum system and condensed at the exhaust that provides a closed-loop for containing and recovery.

Sterilization

Sterilization is a process designed to remove or destroy all viable forms of microbial life. In the pharmaceutical industry, two widely used sterilization methods are steam and ethylene oxide (EtO) sterilization. The steam sterilization process uses high-temperature steam to destroy any microbes or bacterial spores. The effectiveness of this process relies greatly upon the repeatability of the evacuation pulsation to remove air and ensure that the steam penetrates the product. Vacuum systems are relied on heavily for their ability to evacuate the sterilization chamber and handle the gases present.

EtO sterilization, however, uses ethylene oxide, a toxic, flammable gas that breaks down microorganisms on a chemical level. EtO sterilization is often preferred for sterilizing temperature or moisture-sensitive products and requires that they be preconditioned in a controlled environment of temperature and humidity. Similar to steam sterilization, the effectiveness of this process relies on a controlled environment and sterilization chamber. Kinney’s liquid ring vacuum pump has been a preferred solution in EtO sterilization due to its water sealing and ability to handle flammable gases.

Vacuum Pumps for Plastics

Extruder Degassing

By mixing and melting at high temperatures, various gases distribute uniformly from plastics. Kinney A Series vacuum pumps pull vacuum from extruder vents to enhance devolatilization efficiencies. A Series pumps can be offered as water-sealed or oil-sealed. KVA series rotary vane pumps are also offered for this application. The typical vacuum requirement for extruder degassing is 23 to 26” Hg.

Vacuum Thermoforming

Thermoforming is a manufacturing process where a plastic sheet is heated to a malleable forming temperature. The sheet or “film” is heated to a high enough temperature that it can be stretched into or onto a mold using a vacuum. Kinney offers our A or KLRC series water-sealed or oil-sealed liquid ring vacuum pumps and KVA series rotary vane vacuum pumps for this application. The typical vacuum requirement is 21 to 24” Hg.

Vacuum Sizing Tank (Calibration Table)

After the extruder, plastic pipes/profiles pass to a vacuum sizing tank also known as a calibration table. Water is used continuously in a vacuum sizing tank for cooling and lubrication of the plastic profiles. Vacuum is used to improve the shape/profile of the plastics. A vacuum pump used in this step of the process must be capable of handling slugs of water. Kinney’s axial flow design A series liquid ring vacuum pump is proven in this application due to the following benefits:

- Reduced stress on motor shaft & bearing with the axial flow design.

- The shrouded rotor does not leave blades exposed and allows the pump to start flooded.

- Discharge port on the port cylinder has a much larger opening than the flat plate design, this enables it to handle slugs of water and reduces the chance of air being trapped in the pump once the mass flow drops.

- Axial flow design eliminates valves or balls on the discharge side for ease of maintenance.

- The typical vacuum requirement is 18 to 22” Hg.

Plastic Resin & Compound Production

Vacuum pumps are used to pull the pressure off the reactors. This allows the plastic to expand in the vessel. The majority of what is being pulled off is water with some plasticizer. Some products require solid vacuum to reach quality requirements. Our KLRC series liquid ring vacuum pumps have been used successfully in this application for many years. Our two-stage design achieves a deeper vacuum and there are options available for partial once-through recovery for this application. The typical vacuum requirement is 24 to 28” Hg.

Wire Coating

Rubber or nylon material in solid is form fed into the extruder. After passing the heating zone in the screw extruder, it melts and flows into the crossheads where metal wire is continuously traveling. Kinney A series vacuum pumps are used to draw the air in the crossheads so the plastic or rubber melt can create a tight jacket around the wire. The typical vacuum requirement is 23 to 26” Hg.

Corrugated Pipe Manufacturing

The large diameter corrugated pipe manufactured in an extruder is called corrugators. Vacuum is used in this process primarily to hold the melted plastic in the corrugated mold in order to give the desired shape of the pipe. A vacuum pump also extracts the fumes or gases released from the melt. Oil-sealed liquid ring vacuum pumps or rotary vane vacuum pumps are often used in this application. Kinney offers both with our KLRC series and our KVA series vacuum pumps. The typical vacuum requirement is 21 to 24” Hg.

Pneumatic Conveying

Pneumatic conveying is achieved by creating a pressure differential along a pipeline and using the air that moves toward the area of lower pressure to move bulk material. This process can be performed with a vacuum inducer or by injecting compressed air into one end of a pipeline. Like other air moving technologies, M-D Pneumatics s rotary positive displacement design provides constant flow irrespective of pressure. Our blowers have been successful in these applications for over 60 years. M-D Pneumatics rotary positive displacement blowers are used to move plastic pellets, flakes or chips in either vacuum or pressure dilute phase pneumatic conveying in ranges from 17” Hg vac (-575 mbar g) to 15 PSIG (1.01 bar g).

Water & Wastewater Vacuum Pumps

Aeration

Wastewater aeration provides additional air into wastewater in order to aid aerobic microorganisms in the consumption and biodegradation of pollutants, thereby increasing the levels of carbon dioxide, nitrogen, and water. A sufficient and evenly distributed oxygen supply in an aeration system is key to achieving an economically susta inable and effective wastewater treatment program. M-D Pneumatics blowers are commonly used in the activated sludge process where air is pumped into a tank and recirculated back into the aeration basin in order to increase the rate of decomposition. Due to the contaminants present, wastewater must be treated prior to being put back into the environment, making it a highly standardized and monitored process.

inable and effective wastewater treatment program. M-D Pneumatics blowers are commonly used in the activated sludge process where air is pumped into a tank and recirculated back into the aeration basin in order to increase the rate of decomposition. Due to the contaminants present, wastewater must be treated prior to being put back into the environment, making it a highly standardized and monitored process.

Steam Recompression

Blowers are often used in wastewater treatment solutions for their ability to reach specific flow and pressure requirements demanded by each application while still tolerating the harsh environment of mechanical vapor recompression (MVR). Because vapor recompression often includes water injection to help keep the working fluids saturated for condensation and to generate heat waste into energy for re-use, blowers are ideal to help reduce downtime and increase the product lifespan.