Kerr Vertical Process Pump – 5500 Series

Kerr Pump & Supply is the most respected name in vertical process pumps. Kerr’s innovative, heavy duty, time-proven design combines advanced hydraulic engineering with mechanical craftsmanship to meet a wide range of industrial applications. Each pump is engineered with the objective of performing on a continuous duty operation with the longest possible life and a minimum amount of maintenance.

Available in iron or alloy construction, Kerr pumps are able to handle the varied requirements of the metal finishing, parts washing and industrial chemical process industries. Simplicity of design eliminates pump priming, troublesome shaft sealing problems and the inherent maintenance costs of mechanical seals.

Outstanding quality features included in every Kerr pump contribute to longer pump life. Each component has a machined registered fit at all assembly points to assure positive alignment and vibration free.

- Capacities to 3600 GPM

- Heads to 250 feet

- Temperatures to 180 ºF

- Cast iron and alloy construction

- Flexibility on pump extensions and deliveries

- Externally adjustable impeller

- Always primed

- Minimum maintenance costs

- No stuffing box leakage

- Lower installation costs

- Less space required

- Tank pump down option

Applications

- Parts washers

- Spray booths

- Paint systems

- Coolants

- Plating

- Phosphatizing

- OEMs

Kerr Vertical Process Pump – 5180 Series

Kerr’s Model 5180, maintains the rugged feature laden design of Kerr’s standard vertical pumps, at a more economical price. Standard with most units are 300 Series stainless steel liquid ends with high efficiency impellers. These corrosion resistant volutes compare favorably with the cast iron offerings of other suppliers.

Simplicity of design eliminates the need for external impeller adjustment, pump priming, troublesome shaft sealing and the inherent maintenance costs of mechanical seals.

Outstanding quality features included in every Kerr pump contribute to longer pump life. Each component has a machined registered fit at all assembly points to assure positive alignment and vibration free service. Kerr pumps are a sound investment in the best available technology – at no additional cost.

- Capacity up to 300 gpm

- Heads To up to 200 ft

- Temperature 180 ºF

- Speed 1750 rpm 3450 rpm

- Materials of Construction Cast Iron Alloy

- Always primed

- Minimum maintenance costs

- No stuffing box leakage

- Lower installation costs

- Less space required

- Continuous duty operation

- Flexibility on pump extensions and deliveries

Applications

- Parts washers

- Spray Systems

- Machine Tools

- Coolants

- General Industrial

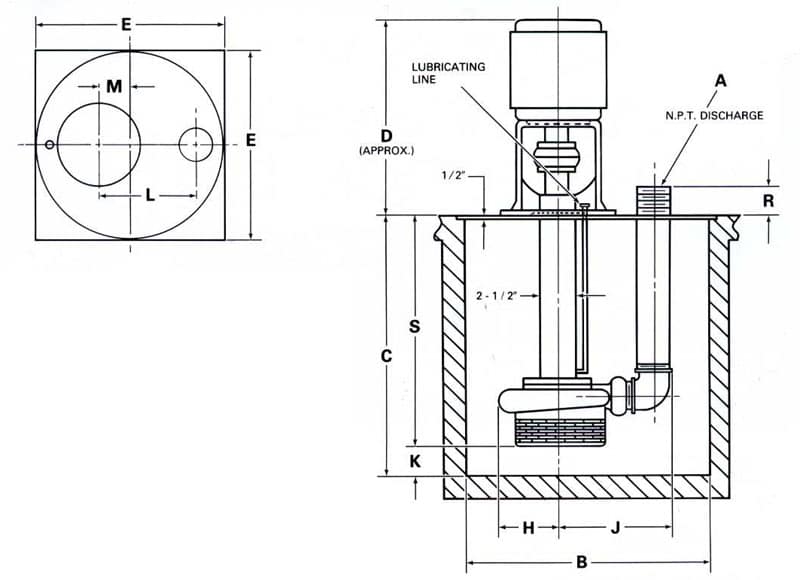

Kerr Industrial Sump Pump – 5220 Series

- Capacity Range – 1 through 40 horsepower, 50 to 1200 GPM.

- All Iron or optional Special Fitted and 316 Stain less Steel Construction.

- Sump Depths from 2 to 25 feet.

- Shaft Guide Bearing Assemblies – for non-corrosive and corrosive liquids, and non-abrasive and abrasive service.

- Elevated Thrust Bearing Design Option.

- Stuffing Box Design Option – for shaft sealing and vapor containment.

- Chairbracket or C-Faced Motor Mount Design,

- Semi-Open Impeller Design.

- Float Switch Assembly – with optional watertight, explosion-proof and mechanical alternator switches.

Applications

- Sump Drainage

- Liquid Transfer

- Dewatering Service

- Industrial Processes

- Pollution Control

- Power Plants

- Process Plants

5220 Sump Pump Dimensions

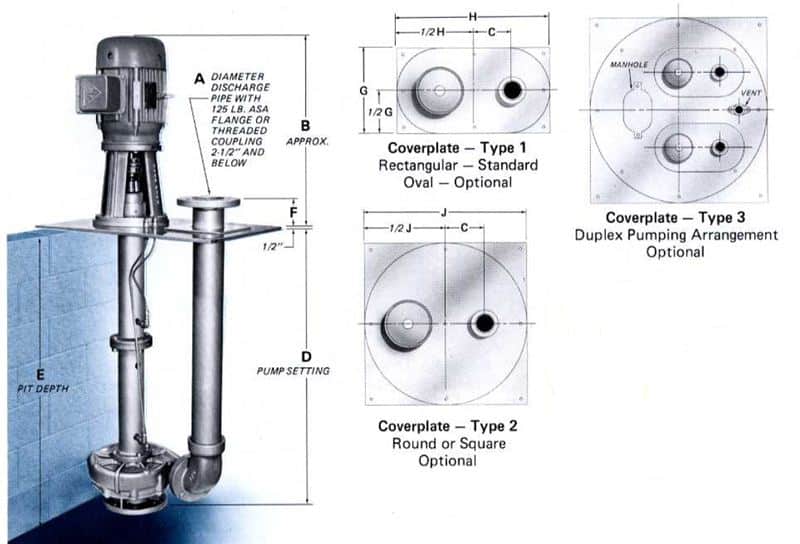

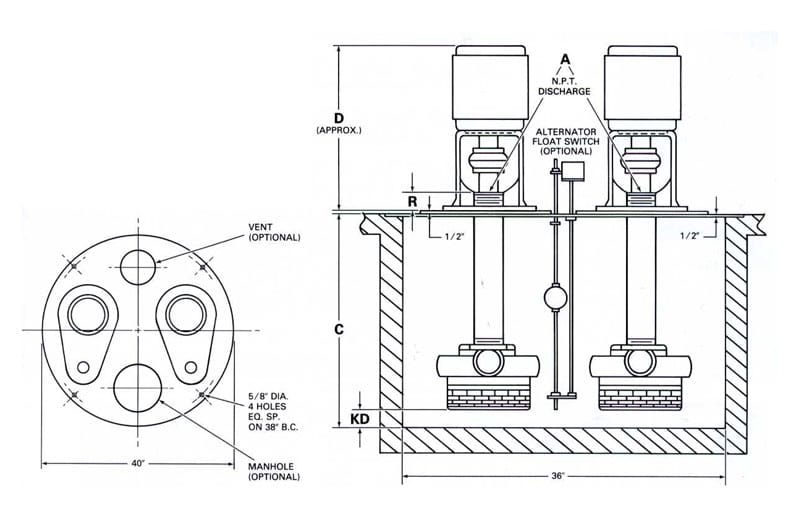

Kerr Vertical Process Pump – 5210 Series

Type A, Duplex and Type B

Kerr 5210 Series Sump Pumps have been designed for use in heavy duty industrial, chemical, municipal, and commercial application. Pump construction is available in all iron and bronze fitted. Call us for 316 S.S. construction applications.

The pump shaft is 1″ diameter, ground and polished and is supported by a heavy duty ball thrust bearing. Pump impeller can be externally adjusted at thrust bearing area. Columns are of flange design for ease of maintenance. Motors and float switch assemblies are furnished per job requirement. Open drip proof, totally enclosed and explosion proof are available.

5210 Sump Pump

Type “A” units are furnished with a cover plate for mounting over a pit.

Also available in Duplex (two pumps)

Type “B” units are furnished without a cover plate and discharge pipe and can be placed on the floor of the pit.