This month, we are featuring Alfa Laval, the largest heat exchanger manufacturer in the world. Alfa Laval has many different types of products but we will focus on heat exchangers, specifically gasket plated and frame heat exchangers.

First, if you already using an Alfa Laval Heat Exchanger, here are some tips to make sure it stays in top condition. If you need help with parts, give us a call.

- Make sure that the operating conditions comply with the design specifications.

- On a daily basis, check for any changes in temperature or pressure and check for any signs of external leaks.

- On a regular basis, keep the tightening bolts, clean and lubricated.

- Protect heat exchangers from water splash and rain. Avoid exposure to ultra violet rays and ozone typically generated from electrical sources.

- Only use genuine spare parts for guaranteed performance, reliability and equipment life. Maintain a stock of essential spare parts and follow the storage instructions.

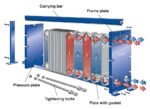

Gasketed Plate Heat Exchangers

This is Alfa Laval’s most cost-effective solution available for industry applications.

High energy efficiency

The innovative plate design creates superior flow distribution across the entire plate surface. This results in excellent heat transfer and high energy efficiency thanks to the elimination of stagnant zones and reduced risk of fouling.

Compact Size

The compact design of our gasketed plate heat exchangers makes it fit in compact spaces. They come equipped with all features needed for easy installation and quick start up.

Plates

The heat-transfer surface is plates that are pressed with herringbone corrugation pattern. When two plates are super imposed with opposing herring bone patterns, this type of corrugation generates a helix- like flow with very high turbulence. Therefore it will be producing the essential condition for achieving high transfer coefficients and effective heat exchanger self-cleaning. By changing the corrugation pattern, the heat exchanger can be used in different processes, even those with very dirty media.

Special Plates

Also called double-wall plates, these must be used with fluids that cannot mix.

Channel Types

There are two plate corrugations (L and H)

- L: Low theta

- H: High Theta

- L+L= L Channel

- L+H=M Channel

- H+H= H Channel

Characteristics

- Low turbulence and pressure drop = L Channels

- Medium turbulence and pressure drop = M Channels

- High turbulence and pressure drop = H channels

Advantages

- Efficient heat transfers

- High Turbulence

- Variable Thermal Length

- Low Pressure Drops

Benefits

- Increased heat recovery

- High self cleaning co-efficients

- Low heat transfer surface area

- Low pumping costs

Frame

- Bearing Box – Makes opening and closing the heat exchanger easier and will reduce maintenance time and increase staff safety.

- Key hole bolt opening – reduces risk of tightening bolts falling out and allows bolt to be removed sideways. Will reduce installation and maintenance cost and ensure staff safety.

- Lock washer – requires one man instead of two to loosen the tightening bolts and reduce the risk of bolts falling out. Will reduce maintenance cost and increase staff safety.

- Elongated nuts – reduces nuts seizing on tightening bolt and will reduce cost for maintenance and spare parts.

- 5-points alignment system and perpendicular corner guidance – Perfect plate alignment avoiding plate pack leakages and alignment of additional necessary openings & closings of the plate heat exchanger. Will reduce maintenance time and spare part cost.

Free Downloads

For more information, visit our Alfa Laval page, or contact sales directly.