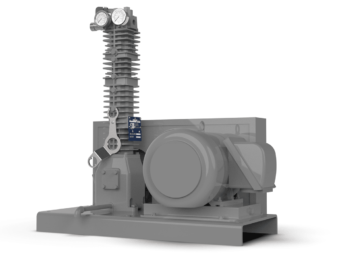

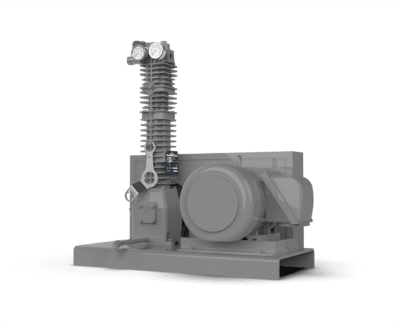

Corken E91 Plant Oil Extraction Compressor System – UL Certified

Kerr Pump recommends Corken’s most innovative vapor recovery compressor for plant oil extraction, the E91 triple-packed compressor . The fully UL Certified triple-packed compressor system provides the safest and most reliable gas containment for indoor or outdoor use. Plant oil extraction compressor systems can separate the desired components on a large scale.

CBD is a growing opportunity for plant oil extraction. Desirable compounds such as cannabidiol (CBD), tetrahydrocannabinol (THC), and terpenes are separated from the rest of the plant using hydrocarbon extraction. Other forms of extraction include ethanol and carbon dioxide (CO2); however, hydrocarbon is a more widely used since it’s more efficient and cost effective.

CBD is a growing opportunity for plant oil extraction. Desirable compounds such as cannabidiol (CBD), tetrahydrocannabinol (THC), and terpenes are separated from the rest of the plant using hydrocarbon extraction. Other forms of extraction include ethanol and carbon dioxide (CO2); however, hydrocarbon is a more widely used since it’s more efficient and cost effective.

Given the various indoor manufacturing environments involved in plant oil extraction, it is more critical than ever to ensure the equipment used has been fully UL Certified for Indoor Use. The Corken E91 compressor is the only fully UL Certified compressor system for the plant oil extraction industry. Additionally, Corken is certified to Good Manufacturing Practice (GMP), European Union ATEX Directive, European Union Machinery Directive, ISO 9001 Standard on Quality Management Systems, and ISO 14001 Standard on Environmental Management Systems.

Botancial Oil Extraction Using a Reciprocating Compressor/Vapor Recovery Pump

The Corken E91 reciprocating gas compressor is oil free so there is no contamination of the process gas stream and has three sets of packing between the crankcase and compression chamber to ensure safest containment of process gas for indoor or outdoor use.

Features and benefits:

- PTFE trim and nickel coated parts: Compatible with food grade materials

- Faster recovery time: Allows more production runs

- Zero psig evacuation pressure: Minimizes waste

- Self-lubricating PTFE piston rings: Low friction design provides many hours of trouble-free service

- Quiet operation: Suitable for indoor applications (approximately 85 dBa at three feet)

- Air compressor is not required: Space saving

- Adjustable packing screw: Extends life of the packing

- Cost effective: Does not require air compressor and pneumatic driver. Avoid possible air/propane cross contamination

- Full Compressor System: UL 1861 Certified

- Motor: UL and CSA compliant and suitable for Class 1, Division 1, Group C & D application

- Optional purge kit available (Compatible with the 07-01-06 U.S. Environmental Protection Agency Regulations 40 CFR CH Section 264.1053)

Hydrocarbon Extraction Has Four Primary Steps:

Step One (Washing): A cold solvent made of propane or butane-washes over the plant material (biomass) at a low temperature and pressure. This process removes the cannabinoids and terpenes from the biomass and dissolves them into the liquid solvent.

Step Two (Removing the Impurities): This step removes any waxes and lipids left in the solution. Unlike ethanol extraction that requires a day-long winterization process, hydrocarbon extraction has fewer waxes and lipids so the removal process is easier and does not take as much time. In most closed loop systems, a de-waxing column filters out any of the remaining waxes and lipids.

Step Three (Collection): The filtered solvent solution is collected into a new or separate container and the hydrocarbon solvent (propane, butane, or propane butane mix) is purged. Corken’s gas compressors (also known as recovery pump) remove the vapor formed by the solvent solution within the collection tank and returns it to the supply tank so it can be re-circulated.

Step Four (Purification): Depending on the desired final state of the product, a purification process may be necessary. Various methods such as a vacuum purge, centrifugal, and co-solvent separation are used to further refine the product.